2 Molds Forming Egg Tray / Carton Making Machine Computer Control Low Cost

It is a Reciprocating forming type Egg Tray Making Machine. It can make many simple shape and large quantity demand egg trays, apple trays, egg cartons, egg boxes, wine trays, shoe trays, etc..using waste paper as raw material. This type machine uses waste paper as raw material to produce the egg trays for chicken farm factory or other customer who needs the trays.

With this machine production line, investors can turn their waste paper into Money!

It is composed of following sections:

1. Pulping System:

Put the waster paper into the hydrapulper , the paper and water will mix in hydrapulper ,then go to the refiner machine ,refiner machine make the pulp more small and uniform ,then the pulp pump absorb the pulp to the pulp pool .after the second mix in the pulp pool ,the pulp will go to the form machine pulp tank .

2. Forming System :

The vacuum pump will offer the vacuum to make the forming mould absorb the pulp from the pulp tank. One PLC cabinet will control the pulp absorb time ,the finished product will be shaped on the forming mould ,then the transfer mould transfer the products to the drying line ,the air compressor will give the air to blow the products ,then the products will drop down from the mould .Then the products is delivered to the drying line automatically; the water will go back to the water pool recycled.

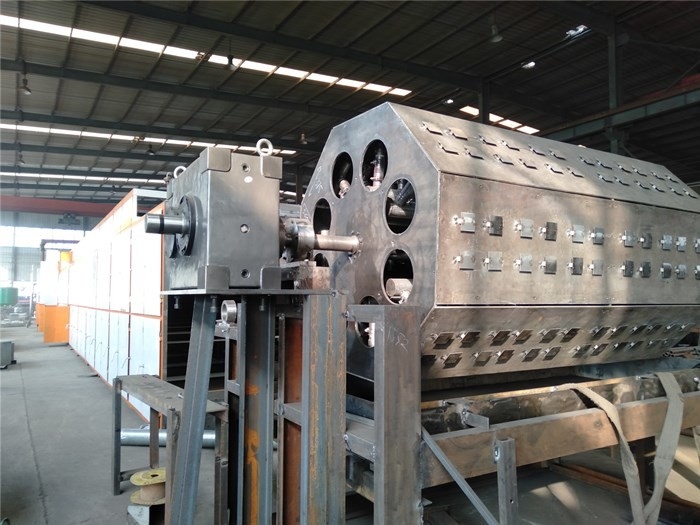

3. Drying system (can use gas,dissel,coal for Boiler burner)

There are burners and blowers on the two sides of the drying line. Burner creates the hot air and the blower increases it. There will be hot air mouth in the drying line also blow the hot air. The drying line is protected by the insulation board. The temperature inside the oven can reach 200 degree.

4. Automatic counting:

After drying line ,the egg trays go to the automatic counting and stacking system. You can preset the quantity of one pile ,such as 100pcs or 200pcs, when the quantity no is done, the counting device will be alarmed. And the products stacked at the same time. You can packaged them directly .

Our machine can be designed to make different products at same time by one Working Table (with 2 Molds or even 3 molds)

All the machine is in computer control, which is also very easy to operate and donnot need high level knowledge requirement for the workers.

Our Paper Egg Tray Machine saves production cost, and saves space. it is quitely used by small medium enterprises.

Our machine can turn your waste paper and books into Money!

Egg Tray Machine Composition

| |

Main sections |

Quantity |

|

Pulping system

|

Including :

water pool—1pcs

mix pool-1pcs

mill pulp pump -1set

water pump-2sets

pulp pump -2sets

1M³pulping machine –1sets

|

1set |

|

Forming system

|

Including

2 moulds forming machine -1set

Vacuum pump-1set

Compressor -1set

Washer –1set

Vacuum tank-1pcs

Air tank—1pcs

|

1set |

Technical data

| Egg Tray Mold Quantity |

2pcs |

| Raw material |

Waste paper |

| Egg tray Capacity |

700pcs/hour |

| Net weight per piece (gram) |

70g-75g |

| Waste paper consumption |

0.06ton / hour |

| Water Consumption |

0.1ton/hour |

| Natural Gas Consumption of Dryer |

25cbm/h |

| Worker requirement |

3-4workers |

| Machine Length |

7m |

| Machine weight |

6-20tons |

| Power Requirement |

Without dryer |

30KW |

| With dryer |

45KW |

| Area of workshop |

Without dryer |

More than100M² |

| With dryer, dryer-18m |

More than240 M² |

| Container Requirement |

Without dryer |

20ft*1 |

| With dryer |

40ft*2+20ft*1 |

| Remarks: 1. The egg tray Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g). 2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant. |

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

35Working days after deposit |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE or 30% TT Deposit + 70% LC |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

| Installation |

| 1.Usually, all installation and debugging work will be done before shipment. 2. If the buyer wants to Install the debugging term, the seller will arrange one people instructs the installment(all travel ticket and hotel charge by buyer and egineer charge USD100/day ) |

Our Machine Advantages:

1. Controlled by automatic computer soft ware

2. No need for installation, machine can start running only after connecting some pipes, power and water, and preparing the material

3. Some parts are Germany brand or other famous brand

4. Our egg tray machine can make different trays at same time by using different moulds

5. Besides egg tray, fruit trays, our machine also can produce industrial package

6. All installation and debugging work will be done before shipment.

7. 20 years' experience on egg tray machine

8. 2 years warranty time

Factory Introduction

Jinan Wanyou Packing Machinery Factory is a famous packing machinery company which has a good mix of science, industry and trade.

It has been devoting to studying, developing, and manufacturing of packing machinery for more than ten years.

It absorbs advanced technology and industrial arts at home and abroad, and has studied and developed ZSJ series paper pulp molding plant, YS series paper carton automatic print fluting machine, BD series thin cutter paper slitter and paper carton series cutter chain.

These products are sold to many countries and areas, such as Algeria, Tunisia, Argentina, Vietnam, Russia, Uzbekistan, Nigeria, Taiwan and so on.

FAQ :

1. What is Semi Automatic type ?

If only order the pulping system and the forming system, that's Semi Automatic type.

And you'll have to do the work of drying up the trays manually;

2. What is Fully Automatic type ?

The Fully Automatic production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.

3. Quality

--- Our machines use UK Technics and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years’ lifespan .

-- The Egg tray molds material is Aluminum which can keep the fixed shape much better than that made of rubber material.

--- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

--- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .

---Some spare parts are made by famous company in Germany

Welcome to contact us!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!