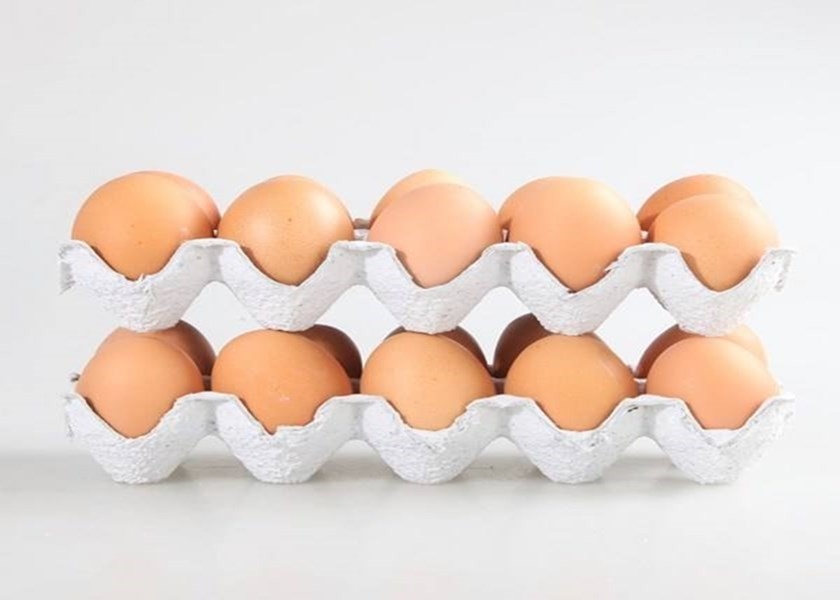

Paper Egg Tray Machine Using Waste Paper As Raw Material to Make Egg Tray / Egg carton

Paper Egg Tray Machine Using Waste Paper As Raw Material to Make Egg Tray / Egg carton is used to make simple shape paper egg trays. It has following main working process: pulping system, forming system and drying system. Paper Egg Tray / Apple Tray making machine Pluping system is in charge of mixing the waste paper and water. When it reaches the certain concentration, the waste paper pulp can be conveyed to forming machine, here it forms a paper egg tray. Then the egg tray paper needs to be dried because the paper egg tray has some water after forming. After this process, you can pack the paper egg tray manually or automatically.

Our Paper Egg Tray Machine saves production cost, and saves space. it is quitely used by small medium enterprises.

And this type machine has following capacities: 350,700,1000,1300pcs per hour. The machine uses waste paper as raw materials. Also the paper cup with PE film can be treated by our machine. We can add crusher to the machine pulping part to crush the PE film or plastic things. And with the vibrating screen, the waste film or plastic things will be moved out from the pulping pool. Our machhine is all in computer control, which has high efficiency and usage.

Quick Detail

Condition: New

Product Type: Egg Tray Machine

Processing Type: Pulp Molding Machine

Place of Origin: Shandong, China (Mainland)

Voltage: 220-440V

Power(W): 28kw~50kw

Dimension(L*W*H): 2300mm*1950mm*1600mm

Weight: 4 tons-20tons

Certification: CE & ISO

Warranty: 2 years

After-sales Service Provided: Engineers available to service machinery overseas

Capacity: 350pcs/h -1300 pcs/h

Color: As customer needs

Frequency: 50Hz-60Hz

Application: egg tray,fruit tray,bottle tray

Workshop required: 50-180㎡

Worker required: 5-6 persons

Fuel: Coal, Natural Gas, Disel, LPG and so on

Automation: Semi-auto and fully automatic

Keyword: Egg tray machine

Our machine is:

1. controlled by computer, no needs any basic construction.

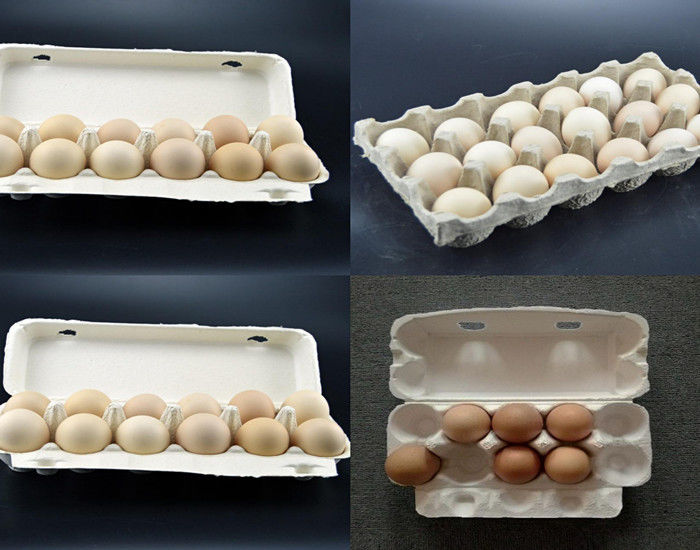

2. We could make all kinds of moulds for you, and it's very easy to change any moulds to the machine.

3. England technology, and spare parts is very famous brand from Germany, Taiwan...

4. with 2years warranty.

5. The installation of the whole line is easy.

Technical data

| Egg Tray Mold Quantity |

1pcs |

2pcs |

3pcs |

4pcs |

| Raw material |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

| Egg tray Capacity |

350pcs/hour |

700pcs/hour |

1000pcs/hour |

1300pcs/hour |

| Net weight per piece (gram) |

70g-75g |

70g-75g |

70g-75g |

70g-75g |

| Waste paper consumption |

0.025ton / hour |

0.06ton / hour |

0.1ton / hour |

0.13ton / hour |

| Water Consumption |

0.05ton / hour |

0.1ton/hour |

0.15ton / hour |

0.2ton / hour |

| Natural Gas Consumption of Dryer |

12cbm/h |

25cbm/h |

35cbm/h |

50cbm/h |

| Worker requirement |

2-3workers |

3-4workers |

4-6workers |

4-6workers |

| Power Requirement |

Without dryer |

20KW |

30KW |

40KW |

45KW |

| With dryer |

30KW |

45KW |

60KW |

65KW |

| Area of workshop |

Without dryer |

More than100M² |

More than 100 M² |

More than 120 M² |

More than 150 M² |

| With dryer |

More than200 M² |

More than 240 M² |

More than300M² |

More than 320 M² |

| Container Requirement |

Without dryer |

20ft*1 |

20ft*1 |

40ft*1 |

40ft*1 |

| With dryer |

40ft*1+20ft*1 |

40ft*2+20ft*1 |

40ft*2+20ft*1 |

40ft*3 |

| Remarks: 1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g). 2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant. |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 25 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE. |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

FAQ :

Our productionline has Fully Automatic and Semi Automatic two types , both have computer control system .

1. What is Semi Automatic type ?

If only order The 1st and 2nd compulsory parts , that's Semi Automatic because you'll have to do the work of drying up egg tray manually;

2. What is Fully Automat type ?

Meaning: the production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.

3. Quality

--- Our machines use UK Technics and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years’ lifespan .

-- The Egg tray moulds material is Aluminium which can keep the fixed shape much better than that made of rubber material.

--- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

--- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .

Our machine can provide customer 2 years warranty, which no other factory can supply.

Our machine has sold out to many countries like India, South Africa, Mali, Nigeria, Alegria, Phillippines, Vietnam, Indonesia, Turkmenistan, Uzbekistan, Tunisia, etc. And we got good reputations from our customers abroad.

Welcome to contact us.

Different molds forming at one time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!