Product Description:

The Egg Tray Production Line is a highly efficient and advanced manufacturing solution designed to meet the growing demand for eco-friendly and sustainable packaging materials. This comprehensive system integrates cutting-edge technology and robust engineering to deliver superior quality egg trays with remarkable speed and precision. At the heart of this production line is the Automatic Egg Tray Machine, which ensures seamless operation and minimizes manual intervention, thereby enhancing productivity and reducing labor costs.

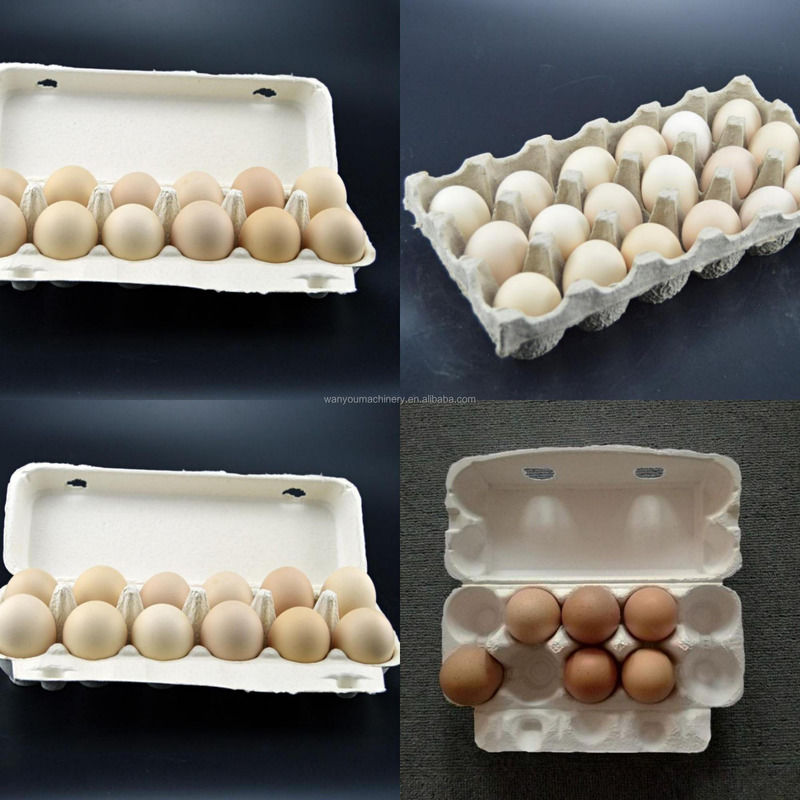

The Egg Tray Machine Equipment is engineered to handle various raw materials such as recycled paper pulp, cardboard, and other biodegradable substances, making it an environmentally responsible choice for businesses focused on sustainability. The production line is capable of producing egg trays of different sizes and shapes, catering to diverse market needs, including trays for eggs, fruits, and other fragile items. This versatility makes the Egg Tray Manufacturing System an ideal solution for packaging companies, poultry farms, and distributors looking to optimize their packaging processes.

One of the standout features of the Automatic Egg Tray Machine is its fully automated operation, which encompasses the entire production cycle—from pulp preparation, molding, drying, to stacking. The integration of advanced control systems allows for easy monitoring and adjustment of production parameters, ensuring consistent quality and reducing material wastage. Additionally, the machine is designed with user-friendly interfaces and automated fault detection mechanisms, which enhance operational safety and minimize downtime.

The Egg Tray Machine Equipment includes several key components such as the pulp making system, molding machine, drying system, and packing unit. The pulp making system efficiently processes raw materials into a smooth slurry, which is then fed into the molding machine to create uniform egg trays. Following molding, the drying system rapidly removes moisture from the trays, ensuring they attain the required hardness and durability. The final packing unit organizes and stacks the finished trays, ready for shipment or storage. This streamlined workflow significantly boosts production capacity while maintaining high standards of product quality.

Moreover, the Egg Tray Manufacturing System is designed with energy efficiency and environmental protection in mind. Many models incorporate energy-saving motors and eco-friendly drying technologies that reduce power consumption and lower carbon emissions. The use of recycled materials not only supports circular economy principles but also helps companies reduce their ecological footprint. This makes the production line not only a profitable investment but also a responsible choice for businesses committed to green manufacturing.

In addition to its technical prowess, the Egg Tray Production Line offers excellent scalability and customization options. Manufacturers can choose from various configurations and capacities to suit their specific operational requirements. Whether a small startup or a large-scale enterprise, this system can be tailored to fit budget constraints and production goals. Furthermore, comprehensive after-sales support and training services ensure that users can maximize the potential of the equipment and maintain smooth operations over time.

In summary, the Egg Tray Production Line featuring the Automatic Egg Tray Machine represents a state-of-the-art solution for producing high-quality, environmentally friendly egg trays efficiently and reliably. Its integration of advanced Egg Tray Machine Equipment with an intelligent Egg Tray Manufacturing System provides businesses with a competitive edge in the packaging industry. By investing in this production line, companies can achieve higher output, reduce operational costs, and contribute positively to environmental sustainability, making it a smart and future-proof choice in today’s market.

Features:

-

High-efficiency Pulp Egg Tray Production process

-

Advanced Egg Tray Manufacturing System for consistent quality

-

Automated Pulp Egg Tray Production line reducing labor costs

-

Durable and eco-friendly egg trays made from recycled pulp

-

Customizable tray sizes and shapes to meet different requirements

-

Energy-saving design for cost-effective operation

-

Easy to operate with user-friendly control system

-

Integrated drying and stacking units for streamlined production

-

Low maintenance requirements ensuring long-term reliability

-

Environmentally sustainable solution supporting green manufacturing

Technical Parameters:

|

Product Name

|

Egg Tray Assembly Line

|

|

Equipment Type

|

Egg Tray Machine Equipment

|

|

Production Capacity

|

Up to 8,000 egg trays per hour

|

|

Material

|

Recycled paper pulp

|

|

Power Supply

|

380V, 50Hz, 3-phase

|

|

Total Power

|

45 kW

|

|

Machine Dimensions

|

12m (L) x 2.5m (W) x 3.2m (H)

|

|

Automation Level

|

Fully automatic

|

|

Control System

|

PLC control with touchscreen interface

|

|

Water Consumption

|

Approximately 0.8 tons per hour

|

|

Weight

|

Approximately 3500 kg

|

|

Application

|

Production of egg trays and pulp molded packaging

|

Applications:

The Wanyou Egg Tray Production Line, model RL-ZJM, originating from Jinan, Shandong, China, is an advanced and reliable solution designed to meet the growing demands of egg tray manufacturing. This Egg Tray Machine Equipment is ideal for various application occasions, ranging from small-scale egg farms to large industrial packaging units. Its versatility makes it suitable for producing egg trays that protect eggs during transportation and storage, ensuring minimal breakage and maintaining egg quality.

The Egg Carton Making Line from Wanyou is perfect for businesses involved in egg packaging, distribution centers, and agricultural cooperatives looking to enhance their packaging efficiency. This production line supports a minimum order quantity of just 1 set, making it accessible for startups and established companies alike. With a supply ability of 1 set per month and a delivery time of 60-90 working days after receiving the deposit payment, customers can plan their production schedules accordingly.

In scenarios such as commercial egg farms, food processing plants, and packaging warehouses, the Egg Tray Assembly Line proves invaluable. It automates the manufacturing process, significantly reducing labor costs and increasing output precision. The equipment is packaged securely in containers to ensure safe delivery. Payment terms for this product are flexible, including T/T, L/C, Western Union, and MoneyGram, facilitating smooth transactions for buyers worldwide.

Although the Wanyou Egg Tray Production Line does not come with certification, its robust build and proven performance make it a trusted choice for those seeking efficient and durable egg tray production solutions. Price negotiations are welcomed, allowing customers to obtain a competitive rate tailored to their specific requirements. Whether for producing biodegradable paper egg trays or molded pulp cartons, this Egg Tray Machine Equipment stands out as a comprehensive solution for egg packaging needs across various industries and application scenarios.

Support and Services:

Our Egg Tray Production Line is supported by a dedicated technical support team committed to ensuring optimal performance and minimal downtime. We provide comprehensive installation guidance, operation training, and regular maintenance services to help you maximize productivity.

Technical support includes troubleshooting assistance, replacement of worn parts, and software updates for automated systems. Our experts are available to offer remote support and on-site service to quickly resolve any issues that may arise during production.

We also offer customized solutions tailored to your specific production requirements, including capacity upgrades and integration with other packaging systems. Comprehensive user manuals and detailed documentation are provided to facilitate smooth operation and maintenance.

Regular inspections and preventive maintenance services are available to extend the lifespan of your equipment and ensure consistent product quality. Our team is committed to helping you achieve efficient, reliable, and cost-effective egg tray production.

Packing and Shipping:

Our Egg Tray Production Line is carefully packaged to ensure safe delivery and optimal performance upon arrival. Each component of the production line is securely wrapped with protective materials to prevent damage during transit. The machinery parts are placed in sturdy wooden crates or reinforced steel frames, depending on the size and weight of the equipment.

For shipping, we offer flexible options including sea freight, air freight, and land transportation to accommodate various customer needs and locations. All shipments are accompanied by detailed documentation, including packing lists, user manuals, and installation guides to facilitate smooth setup and operation.

We also provide professional loading and unloading services to minimize risks during handling. Our logistics team coordinates closely with customers to ensure timely delivery and to address any specific shipping requirements. With our comprehensive packaging and shipping solutions, you can trust that your Egg Tray Production Line will arrive safely and ready for immediate use.

FAQ:

Q1: What is the brand and model number of the Egg Tray Production Line?

A1: The Egg Tray Production Line is branded Wanyou, and the model number is RL-ZJM.

Q2: Where is the Egg Tray Production Line manufactured?

A2: It is manufactured in Jinan, Shandong, China.

Q3: What is the minimum order quantity and price for the Egg Tray Production Line?

A3: The minimum order quantity is 1 set. The price is negotiable depending on the order specifications.

Q4: What payment terms does Wanyou accept for the Egg Tray Production Line?

A4: Payment terms include T/T, L/C, Western Union, and MoneyGram.

Q5: How long does it take to deliver the Egg Tray Production Line after placing an order?

A5: Delivery time is typically 60-90 working days after receiving the deposit payment.

Q6: How is the Egg Tray Production Line packaged for shipment?

A6: The production line is packaged securely in a container to ensure safe delivery.

Q7: What is the supply ability of Wanyou for the Egg Tray Production Line?

A7: Wanyou can supply 1 set per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!