Roatary Forming Egg Tray Machine Egg Tray Production Line Featuring Intelligent Control Panel and Real Time Production Monitoring for Enhanced Management

Product Description:

The Egg Tray Production Line is an advanced and highly efficient system designed for the mass production of egg trays, serving the needs of various industries such as poultry farming, egg packaging, and distribution. This comprehensive production line integrates cutting-edge technology and robust mechanical components to ensure smooth operation, high output, and superior quality of the finished egg trays. Whether you are looking to enhance your existing manufacturing capabilities or establish a new production facility, the Egg Tray Assembly Line offers a reliable and cost-effective solution tailored to meet your specific requirements.

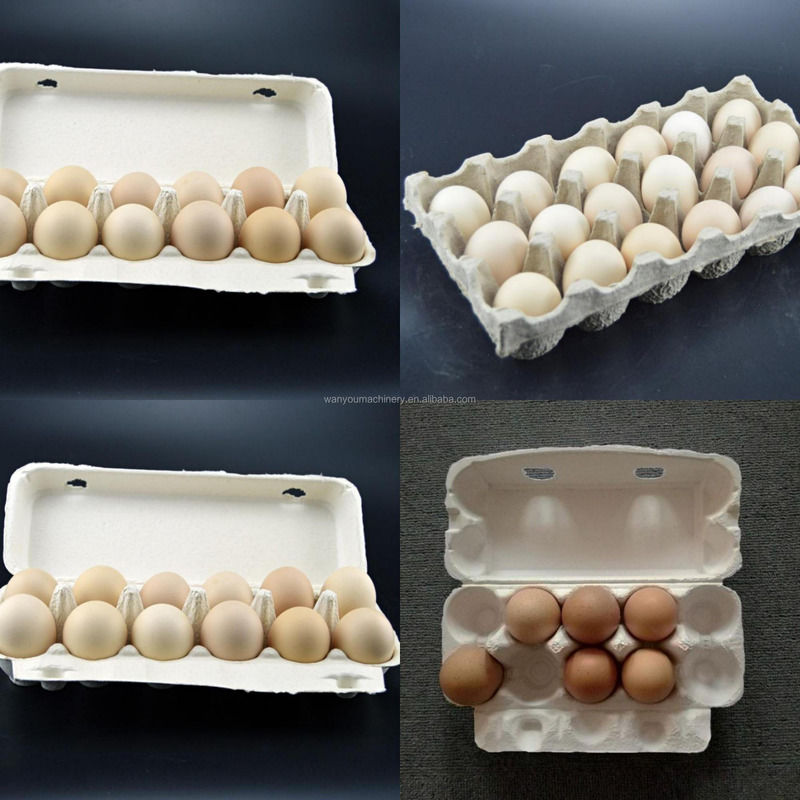

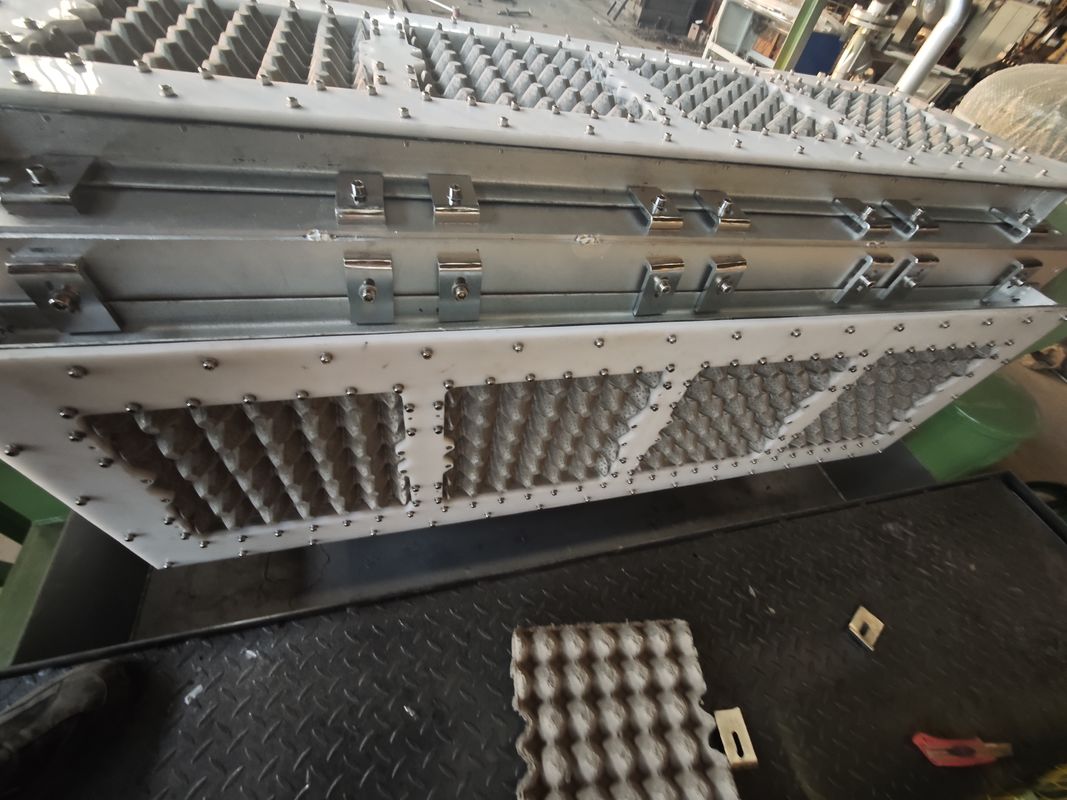

At the core of this production system is the Egg Tray Forming Line, which plays a crucial role in shaping raw pulp materials into sturdy, uniform egg trays. Utilizing a vacuum molding process, the forming line efficiently transforms recycled paper pulp into environmentally friendly trays that provide excellent cushioning and protection for eggs during transportation and storage. The precision-engineered molds and advanced drying mechanisms ensure that each tray possesses consistent thickness, strength, and durability, making them ideal for both commercial and domestic use.

Complementing the forming line is the Egg Tray Packaging Line, an integral part of the complete production setup that streamlines the packaging phase. This packaging line is designed to automatically collect, stack, and bundle the finished egg trays, significantly reducing manual labor and increasing overall productivity. With features such as automatic counting, stacking, and wrapping, the packaging line enhances operational efficiency and ensures that the trays are securely packed for safe shipment. The automation incorporated in this segment minimizes human error and accelerates the packaging process, enabling manufacturers to meet tight deadlines and volume demands effortlessly.

The Egg Tray Assembly Line is engineered for versatility and scalability, accommodating various tray sizes and designs to cater to different customer needs. Manufacturers can easily adjust the settings to produce trays ranging from small quail egg trays to larger trays suitable for chicken or duck eggs. This adaptability is vital for businesses aiming to diversify their product offerings and penetrate multiple markets. Moreover, the modular construction of the assembly line allows for easy expansion and integration of additional equipment, such as pulp preparation systems and drying ovens, to further boost production capacity.

Another significant advantage of the Egg Tray Production Line is its emphasis on environmental sustainability. By utilizing recycled paper materials and implementing energy-efficient technologies, the line supports green manufacturing practices that reduce waste and lower carbon footprints. The production process generates minimal noise and pollution, making it suitable for installation in various industrial environments without causing disruption. Furthermore, the egg trays produced are biodegradable and recyclable, aligning with the growing global demand for eco-friendly packaging solutions.

Operators will appreciate the user-friendly design of the Egg Tray Assembly Line, which incorporates intuitive control panels and automated monitoring systems. These features facilitate easy operation, real-time performance tracking, and quick troubleshooting, thereby minimizing downtime and maintenance costs. The robust construction and high-quality components ensure long-term reliability and durability, providing manufacturers with a sustainable investment that delivers consistent returns.

In summary, the Egg Tray Production Line is an all-encompassing manufacturing solution that combines the Egg Tray Forming Line, Egg Tray Packaging Line, and assembly components into a cohesive system. It delivers exceptional efficiency, flexibility, and environmental benefits, making it an ideal choice for businesses involved in egg tray production. By adopting this advanced production line, manufacturers can achieve higher output, improved product quality, and reduced operational costs, ultimately gaining a competitive edge in the market.

Features:

- High-efficiency Egg Tray Production Line designed for large-scale manufacturing

- Complete Egg Tray Packaging Line ensuring seamless production and packaging process

- Advanced Egg Carton Making Line capable of producing various sizes and designs

- Durable and reliable Egg Tray Machine Equipment built with high-quality materials

- Automated system for pulp molding, drying, and packing to maximize productivity

- Energy-efficient technology reducing operational costs and environmental impact

- User-friendly interface for easy operation and maintenance

- Customizable configurations to meet specific production requirements

- Robust construction ensuring long service life and minimal downtime

- Integrated quality control measures for consistent product standards

Technical Parameters:

| Product Name |

Egg Tray Production Line (Egg Carton Making Line, Egg Tray Machine Equipment, Egg Tray Molded Machine) |

| Production Capacity |

1000-3000 pcs/hour |

| Raw Material |

Waste paper pulp |

| Power Supply |

380V, 50Hz, 3 Phase |

| Total Power |

15 kW |

| Machine Dimensions |

4500mm x 1500mm x 2000mm |

| Weight |

2500 kg |

| Drying Method |

Hot Air Drying / Solar Drying |

| Automation Level |

Semi-automatic / Fully automatic options |

| Control System |

PLC Control System |

Applications:

The Wanyou Egg Tray Production Line, model RL-ZJM, originating from Jinan, Shandong, China, is an advanced Egg Tray Manufacturing System designed to meet the diverse needs of the packaging industry. This robust Egg Tray Packaging Line is ideal for businesses seeking efficient, reliable, and high-capacity production solutions for egg cartons and trays. With a minimum order quantity of just one set, it offers flexibility for both small-scale and large-scale manufacturers aiming to optimize their egg carton making processes.

Primarily, the Egg Tray Manufacturing System is suitable for use in egg farms, packaging plants, and food processing industries where the demand for protective and eco-friendly egg trays is high. The system efficiently shapes pulp into durable egg trays and cartons, ensuring eggs are securely packed and protected during transportation and storage. This makes it an essential piece of equipment for companies focused on improving product safety while reducing packaging waste.

The Egg Tray Packaging Line is also perfectly suited for recycling centers and paper pulp manufacturers. It enables the conversion of recycled paper into new egg trays, promoting sustainability and environmental responsibility. The Wanyou RL-ZJM model supports customized tray sizes and shapes, accommodating various egg packaging requirements, which makes it highly versatile across different market needs.

Moreover, the Egg Carton Making Line can be integrated into broader production workflows, providing seamless automation from pulp molding to drying and packaging. This enhances overall production efficiency and reduces labor costs. With a supply ability of one set per month and a delivery time of 60-90 working days after deposit payment, Wanyou ensures timely fulfillment of orders. Payment terms are flexible, including T/T, L/C, Western Union, and MoneyGram, facilitating smooth international transactions.

Packaging for the Egg Tray Production Line is securely done in containers, ensuring safe delivery worldwide. Although this product does not come with certification, its high performance and durability have earned trust among numerous clients. Price is negotiable, allowing buyers to find a suitable agreement based on their specific production needs and scale. Overall, the Wanyou Egg Tray Manufacturing System RL-ZJM is an excellent investment for any enterprise aiming to enhance its egg tray production capacity and packaging quality.

Support and Services:

Our Egg Tray Production Line comes with comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide detailed installation guidance, including on-site installation assistance and commissioning to help you get started quickly and efficiently.

Our expert team offers thorough training for your staff on operating and maintaining the equipment, ensuring smooth and safe production processes. We also provide routine maintenance services and timely troubleshooting support to minimize downtime and extend the lifespan of your production line.

In addition, we supply genuine spare parts and upgrades to keep your machinery running at peak efficiency. Our customer service is dedicated to responding promptly to any technical inquiries and offering customized solutions tailored to your production needs.

With our Egg Tray Production Line technical support and services, you can achieve reliable, high-quality egg tray manufacturing with peace of mind.

Packing and Shipping:

The Egg Tray Production Line is carefully packaged to ensure safety and integrity during transportation. Each component is securely wrapped with protective materials such as foam and plastic film to prevent damage from shocks and vibrations. The packaging is designed to be compact and sturdy, minimizing space while maximizing protection.

For shipping, the egg tray production line is loaded onto pallets and firmly strapped to avoid movement during transit. Depending on the destination and customer requirements, the equipment can be shipped via sea freight, air freight, or land transportation. All shipments include detailed packing lists and handling instructions to facilitate smooth customs clearance and installation upon arrival.

Our logistics team coordinates closely with reliable carriers to ensure timely delivery and safe arrival of the egg tray production line, allowing customers to commence production with minimal delay.

FAQ:

Q1: What is the brand and model number of the Egg Tray Production Line?

A1: The Egg Tray Production Line is manufactured by Wanyou and the model number is RL-ZJM.

Q2: Where is the Egg Tray Production Line made?

A2: This production line is made in Jinan, Shandong, China.

Q3: What is the minimum order quantity for the Egg Tray Production Line?

A3: The minimum order quantity is 1 set.

Q4: What are the payment terms available for purchasing the Egg Tray Production Line?

A4: Payment can be made via T/T, L/C, Western Union, or MoneyGram.

Q5: How long is the delivery time after placing an order for the Egg Tray Production Line?

A5: The delivery time is typically 60-90 working days after receiving the deposit payment.

Q6: How is the Egg Tray Production Line packaged for shipment?

A6: The production line is packaged securely in a container for safe delivery.

Q7: What is the supply ability of the Egg Tray Production Line?

A7: The supplier can provide 1 set per month.

Q8: Is there a fixed price for the Egg Tray Production Line?

A8: The price is negotiable depending on the order details and requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!