Product Description:

The Egg Tray Production Line is an advanced and efficient solution designed to meet the growing demand for sustainable and eco-friendly packaging materials. This comprehensive Egg Tray Assembly Line integrates modern technology and innovative processes to produce high-quality pulp egg trays that are both durable and environmentally responsible. By utilizing recycled paper and water-based molding techniques, the Pulp Egg Tray Production process minimizes waste and reduces environmental impact, making it an ideal choice for businesses seeking green packaging alternatives.

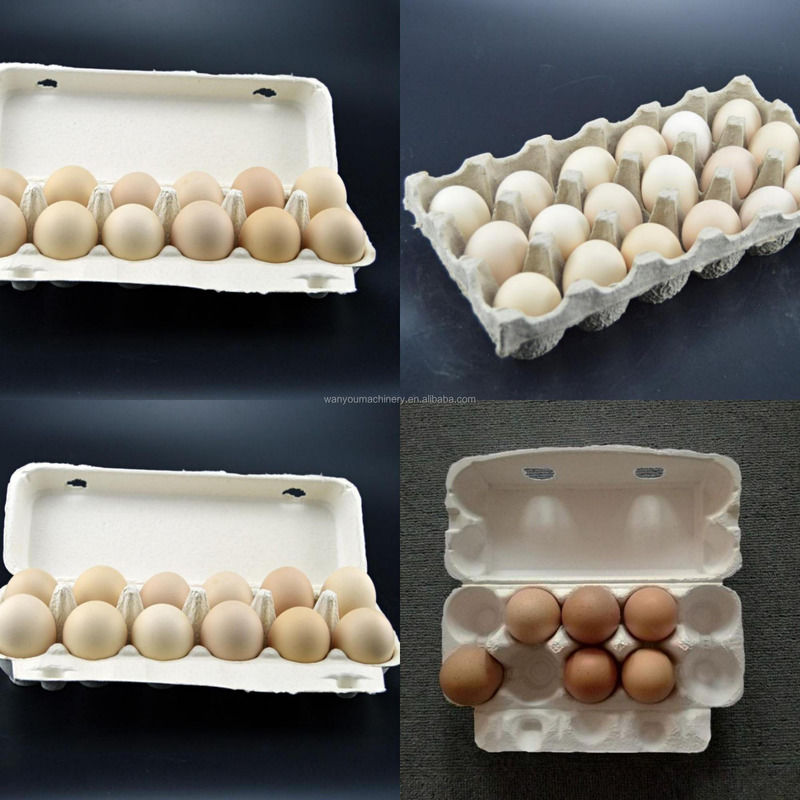

At the core of the Egg Tray Production Line is its automated workflow, which seamlessly combines several key stages including pulping, molding, drying, and packing. The system starts with the pulping unit, where raw paper materials are converted into a homogeneous slurry. This slurry is then transferred to the molding machine, which forms the pulp into precisely shaped egg trays designed to protect eggs during transportation and storage. The mold design is customizable, allowing manufacturers to produce trays with varying capacities and sizes based on specific market requirements.

One of the standout features of this Egg Tray Assembly Line is its high production efficiency. Equipped with advanced mechanical components and automation controls, the assembly line can produce thousands of egg trays per hour, significantly reducing labor costs and increasing overall output. The drying section employs energy-efficient drying technologies that ensure the trays are thoroughly dried without compromising their strength or quality. This results in a final product that is sturdy, moisture-resistant, and ready for immediate use or shipment.

In addition to its operational efficiency, the Pulp Egg Tray Production system is designed with user-friendly interfaces and easy maintenance procedures. Operators can monitor and adjust production parameters in real-time, ensuring consistent product quality and minimizing downtime. The modular design of the Egg Tray Assembly Line also allows for quick upgrades and expansions, catering to the evolving needs of growing businesses.

Environmental sustainability is a key benefit of the Egg Tray Production Line. By using recycled paper as the primary raw material, the production process helps reduce deforestation and the accumulation of waste paper in landfills. Moreover, the biodegradable nature of pulp egg trays ensures that the packaging decomposes naturally after use, contributing to a circular economy and reducing pollution. This eco-conscious approach not only meets regulatory requirements but also appeals to environmentally aware consumers, enhancing brand reputation and market competitiveness.

The versatility of the Egg Tray Assembly Line extends beyond egg trays; it can also be adapted to manufacture other molded pulp products such as fruit trays, seedling pots, and protective packaging for electronics. This flexibility allows manufacturers to diversify their product offerings and tap into new markets without significant additional investment.

In conclusion, the Egg Tray Production Line represents a state-of-the-art manufacturing solution that combines efficiency, sustainability, and versatility. Its advanced Pulp Egg Tray Production technology ensures the consistent delivery of high-quality, eco-friendly packaging products that meet the demands of modern consumers and industries. By investing in this Egg Tray Assembly Line, businesses can achieve significant cost savings, reduce their environmental footprint, and position themselves as leaders in sustainable packaging innovation.

Features:

-

High-efficiency Egg Tray Forming Line for large-scale production

-

Advanced Pulp Egg Tray Production technology ensuring eco-friendly and biodegradable trays

-

Automated Egg Tray Forming Line with precise molding for consistent product quality

-

Energy-saving design reducing operational costs

-

Durable construction for long-term use and minimal maintenance

-

Easy to operate and maintain with user-friendly control systems

-

Capable of producing various sizes and shapes of egg trays to meet different market needs

-

Integrated drying and stacking systems for streamlined production process

-

Environmentally friendly process reducing waste and supporting sustainable manufacturing

Technical Parameters:

|

Technical Parameter

|

Specification

|

|

Product Name

|

Egg Carton Making Line

|

|

Production Capacity

|

1000-3000 pcs/hour

|

|

Raw Material

|

Waste Paper Pulp

|

|

Drying Method

|

Hot Air or Microwave Drying

|

|

Power Supply

|

380V/50Hz (customizable)

|

|

Total Power

|

20-30 kW

|

|

Machine Dimensions

|

Length 10m x Width 3m x Height 2.5m

|

|

Automation Level

|

Fully automatic

|

|

Application

|

Pulp Egg Tray Production

|

|

Equipment Type

|

Egg Tray Machine Equipment

|

Applications:

The Wanyou RL-ZJM Egg Tray Production Line is an advanced solution designed for efficient Pulp Egg Tray Production, ideal for various industrial and commercial applications. Manufactured in Jinan, Shandong, China, this Automatic Egg Tray Machine is perfect for businesses looking to produce high-quality, eco-friendly pulp egg trays with precision and consistency. Its robust design and reliable performance make it suitable for egg packaging plants, agricultural cooperatives, and packaging solution providers seeking to enhance their production capabilities.

This production line is widely used in occasions where sustainable packaging is required, especially in egg processing factories and poultry farms that demand efficient and cost-effective methods to package eggs safely. The Wanyou RL-ZJM model is also suitable for recycling plants that focus on converting waste paper into valuable pulp egg trays, supporting environmental protection efforts and promoting green manufacturing practices.

In scenarios where automation and high output are essential, this Automatic Egg Tray Machine offers seamless operation, reducing labor costs and increasing productivity. Its capability to produce uniform and sturdy egg trays makes it indispensable in large-scale egg distribution centers and wholesale egg suppliers. The machine’s flexibility allows it to cater to different production demands, whether small batch runs or continuous high-volume output.

Businesses interested in the Wanyou RL-ZJM Egg Tray Production Line should note the minimum order quantity is 1 set, with supply ability of 1 set per month. Pricing is negotiable, accommodating various budget considerations. Payment terms include T/T, L/C, Western Union, and MoneyGram, providing convenient options for international buyers. After receiving the deposit payment, delivery time ranges from 60 to 90 working days, with secure packaging in containers to ensure safe transportation.

Although this product does not hold specific certifications, its quality and performance have been trusted by many clients in the pulp egg tray production industry. Whether you are starting a new egg tray manufacturing business or upgrading existing equipment, the Wanyou RL-ZJM Automatic Egg Tray Machine offers a reliable, efficient, and sustainable solution for your production needs.

Support and Services:

Our Egg Tray Production Line comes with comprehensive technical support and services to ensure smooth operation and optimal performance. We provide detailed installation guidance, operator training, and routine maintenance instructions to help you get the most out of your equipment.

Our experienced technical team is available to assist with troubleshooting and resolving any issues that may arise during the operation of the production line. We offer timely updates and upgrades to the software and hardware components to keep your production line running efficiently.

Additionally, we supply readily available spare parts to minimize downtime and extend the lifespan of your machinery. Regular maintenance services can be scheduled to prevent unexpected breakdowns and maintain product quality.

We are committed to delivering reliable and professional support to ensure your Egg Tray Production Line operates at peak efficiency, helping you achieve consistent production output and high-quality egg trays.

Packing and Shipping:

Our Egg Tray Production Line is carefully packaged to ensure safe delivery and optimal protection during transportation. Each component is securely wrapped with protective materials and placed in sturdy wooden crates or reinforced cartons to prevent damage from shocks and vibrations.

The packaging is designed to be weather-resistant and durable, safeguarding the machinery from moisture, dust, and other environmental factors. Clear labeling and handling instructions are marked on each package to facilitate easy identification and proper handling.

For shipping, we offer flexible options including sea freight, air freight, and land transportation to meet the diverse needs of our customers worldwide. Our logistics team coordinates closely to ensure timely dispatch and delivery, providing tracking information and support throughout the shipping process.

Upon arrival, our customers receive detailed unpacking and installation guides, along with professional after-sales service to ensure smooth setup and operation of the Egg Tray Production Line.

FAQ:

Q1: What is the brand and model number of the Egg Tray Production Line?

A1: The Egg Tray Production Line is branded as Wanyou, and the model number is RL-ZJM.

Q2: Where is the Egg Tray Production Line manufactured?

A2: This product is manufactured in Jinan, Shandong, China.

Q3: What is the minimum order quantity for the Egg Tray Production Line?

A3: The minimum order quantity is 1 set.

Q4: What are the payment terms accepted for purchasing the Egg Tray Production Line?

A4: We accept T/T, L/C, Western Union, and MoneyGram as payment methods.

Q5: How long does it take to deliver the Egg Tray Production Line after placing an order?

A5: The delivery time is typically 60-90 working days after receiving the deposit payment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!