Mini Egg Tray Making Machine Paper Egg Tray Machine / Eco-friendly Egg Tray Production Line

This type machine uses waste paper as raw material to produce the egg trays for chicken farm factory or other customer who needs the trays. It has 2 types forming method: one is Reciprocating Type, the other is Rotary Type Egg Tray Making Machine. It can make many simple shape and large quantity demand egg trays, apple trays, egg cartons, egg boxes, wine trays, shoe trays, etc..using waste paper as raw materia

With this machine production line, investors can turn their waste paper into Money!

Our machine is composed of by following system:

Paper Egg Tray Manufacturing Process:

1.Pulp Making Process:

♦Put the waste paper into the hydraulic pulper. After about 40 minutes’ high consistency mixing, the waste paper will be made into rough pulp. The proportion is 1(paper) :3(water).

♦Then the rough pulp will flow into the homogenization pool. The rough pulp will be refined further by the pulp beater in the homogenization pool.

♦The appropriate concentration of the pulp will flow into the finished pulp to supply paper pulp to the forming machine.

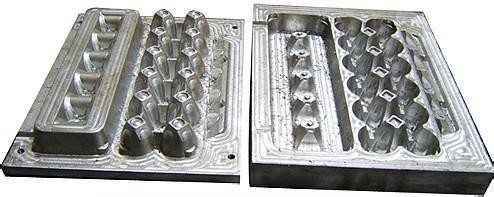

2.Molding Process:

♦By pulp pump, the finished pulp will be transported into the paper tray forming machine.

♦Under the suction power of vacuum pump, the pump will be adsorbed up on molds to form egg tray.

♦Under the blowing force of air compressor, the formed egg tray will drop off from molds.

3.Drying Process:

♦In the egg tray drying process, the extra water component in the wet egg trays can be evaporated. Drying is the essential process. After drying, paper egg trays are not easy for deformation and broken.

Machine Features:

1. controlled by computer, no needs any construction.

2. We could make all kinds of moulds for you, and it's very easy to change any moulds to the machine.

3. England technology, and spare parts is very famous brand from Germany, Taiwan...

4. with 2years warranty.

5. The installation of the whole line is easy.

This production line is suitable for the following products:

Egg tray(30-egg) Egg box/egg carton(6-egg, 10-egg, 12-egg, 6+6-egg, 15-egg, 18-egg and etc)

Fruit tray (for apple,tomato, pear and etc) Cup carrier(4 pack and 2 pack) Seeding tray and bottle trays.

Some medical-care products and fixed shape(the design doesn't change frequently) pulp molding products with large quantity.

Technical parameters(700pcs per hour)

| Egg Tray mould quantity |

2pcs |

| Raw material |

Waste paper |

| Output for egg tray |

700pcs/hour |

| Net weight per piece (gram) |

70g-75g |

| The volume of waste paper consumed |

0.06ton / hour |

| The volume of water consumed |

0.1ton / hour |

| The natural gas consumption of the dryer(about) |

25cbm/h |

| Machine Weight |

10-20tons |

| Egg tray Size |

295mm*295mm 30eggs |

| Product Name |

Model |

Qty(set) |

Capacity |

| Egg Tray Machine |

ZJM-1A |

1 |

700pcs/h |

| Area of workshop |

Without dryer |

More than 100㎡ |

| With dryer |

More than 240㎡ |

| Capacity of power |

Without dryer |

30KW |

| With dryer |

45kw |

| Machine size |

Without dryer |

7m*2m*2.2m |

| With dryer |

26m*2m*2.2m |

| Size of container |

Without dryer |

20ft*1 |

| With dryer |

40ft*2+20ft*1 |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 60 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE or 30% TT Deposit + 70% LC |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

Factory Introduction

Jinan Wanyou Packing Machinery Co.,Ltd is a famous packing machinery company which has a good mix of science, industry and trade.

It has been devoting to studying, developing, and manufacturing of packing machinery for more than ten years.

It absorbs advanced technology and industrial arts at home and abroad, and has studied and developed ZSJ series paper pulp molding plant, YS series paper carton automatic print fluting machine, BD series thin cutter paper slitter and paper carton series cutter chain.

These products are sold to many countries and areas, such as Algeria, Tunisia, Argentina, Vietnam, Russia, Uzbekistan, Nigeria, Taiwan and so on.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!