Semi Automatic Small Paper Pulp Molding Egg Tray Machine Egg Carton Machine PLC Controlled

The Egg Tray production line is mainly combined by THREE PARTS:

1. Pulping system: Use waste paper and water as raw material and pulp up;

2. Forming system: The pulped material being delivered to Product Tray molds, and forming to the Product Tray plate shape;

3. Drying system: The formed Product Tray plate being delivered to Dryer, and come up to Completed Strong Product Tray plate The drying system is with one boiler.

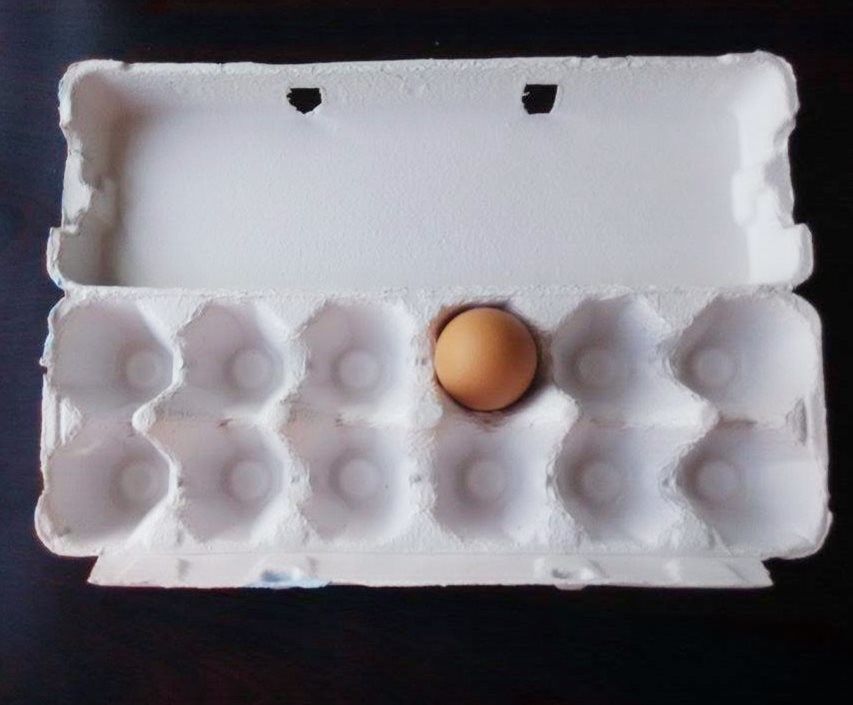

A hot pressing section should be added in the production of pulp molded egg box/carton(6-cell,10-cell,12-cell,6+6-cell,15-cell),fruit tray and cup carrier after drying because of shrinking.

The egg box/carton can be labelled or printed after hot pressing. These processes could be finsihed manually or automatically.

We have variety capacity egg tray machines from 350pcs/h to 2500pcs/h. We are OEM factory, we can manufacture the machine as per your requirement.

All the machine is in computer control, which is also very easy to operate and donnot need high level knowledge requirement for the workers.

Our Paper Egg Tray Machine saves production cost, and saves space. it is quitely used by small medium enterprises.

Our machine can turn your waste paper and books into Money!

This production line is suitable for the following products:

Egg tray(30-egg) Egg box/egg carton(6-egg, 10-egg, 12-egg, 6+6-egg, 15-egg, 18-egg and etc)

Fruit tray (for apple,tomato, pear and etc) Cup carrier(4 pack and 2 pack) Seeding tray and bottle trays.

Some medical-care products and fixed shape(the design doesn't change frequently) pulp molding products with large quantity.

Technical data

| Egg Tray mould quantity |

1pcs |

| Raw material |

Waste paper |

| Output for egg tray |

350pcs/hour |

| Net weight per piece (gram) |

70g-75g |

| The volume of waste paper consumed |

27kg / hour |

| The volume of water consumed |

50kg / hour |

| The natural gas consumption of the dryer(about) |

12cbm/h |

| Machine Weight |

5-20tons |

| Egg tray Size |

295mm*295mm 30eggs |

| Item |

Information |

Notes |

| Workshop Recommendation |

>=200m2 |

Length>=18m;width>=10m;height.>=5m (It could be adjusted according to the user’s existing workshop) |

| Material Type |

Waste paper |

Newspaper, Corrugated Carton, Paper Box, Books, Corrugated Paperboard etc. |

| Material Consumption |

20kg/h-27kg/h |

30packed egg tray(70-75g) |

| Water Consumption |

30-50kg/h |

30packed egg tray(70-75g) |

| Electricity consumption |

20-40Kw |

Full Throttle Operation |

| Fuel Consumption |

LPG 10-20m3/h |

Choose one from the three types of fuel |

| Or Natural Gas 12m3/h |

| Or Diesel Oil 40kg/h |

| Operator Required |

2-3workers/shift |

24hours, 3 shift |

| Container Required for Transport |

2 of 40 ft |

Whole production line |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 25 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE or 30% TT Deposit + 70% LC |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

Factory Introduction

Jinan Wanyou Packing Machinery Factory is a famous packing machinery company which has a good mix of science, industry and trade.

It has been devoting to studying, developing, and manufacturing of packing machinery for more than ten years.

It absorbs advanced technology and industrial arts at home and abroad, and has studied and developed ZSJ series paper pulp molding plant, YS series paper carton automatic print fluting machine, BD series thin cutter paper slitter and paper carton series cutter chain.

These products are sold to many countries and areas, such as Algeria, Tunisia, Argentina, Vietnam, Russia, Uzbekistan, Nigeria, Taiwan and so on.

Don’t miss the chance of promoting the production efficiency of your company.

Welcome to contact us.

FAQ

(1). What kind of material we can use as the raw material?

Any kind of waste paper like old newspaper,magazines,books,A4 paper, corrugated cartons, paperboard etc.

(2). What kind of Fuel can be used for the whole production line?

Coal, natural gas, and dieseal oil.

(3). What kind of products can be made by this machine?

All paperpackage such as paper egg tray, egg carton,egg box, fruit tray, bottle tray, cup tray, consumer product package, medical disposable container etc.

(4). Are you a manufacturer or a trading company?

Yes, our company has been fabricating pulp molding machine since 2000. We are one of the

most important pulp molding machine maufacturers in the world, and we are famous pulp

molding machine manufacturer in China, providing high quality and production capacity pulp molding

machinery at reasonable prices to the world.

(5). How to contact you?

(A) Visit us.Our head office is in Building 5-407, Xinyuanxin International Business Center, Huaxin

Road, Licheng District, Jinan City, Shandong Province, P.R. China.

The nearest airport is Jinan International Airport.

(B) Send email to tell us your requirments.

(C) Call us at +86-531-88030983

(D) Contact us at Whatsapp/Wechat: +86-15665703348, we will be online anytime.

Welcome to contact us!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!