Product Description:

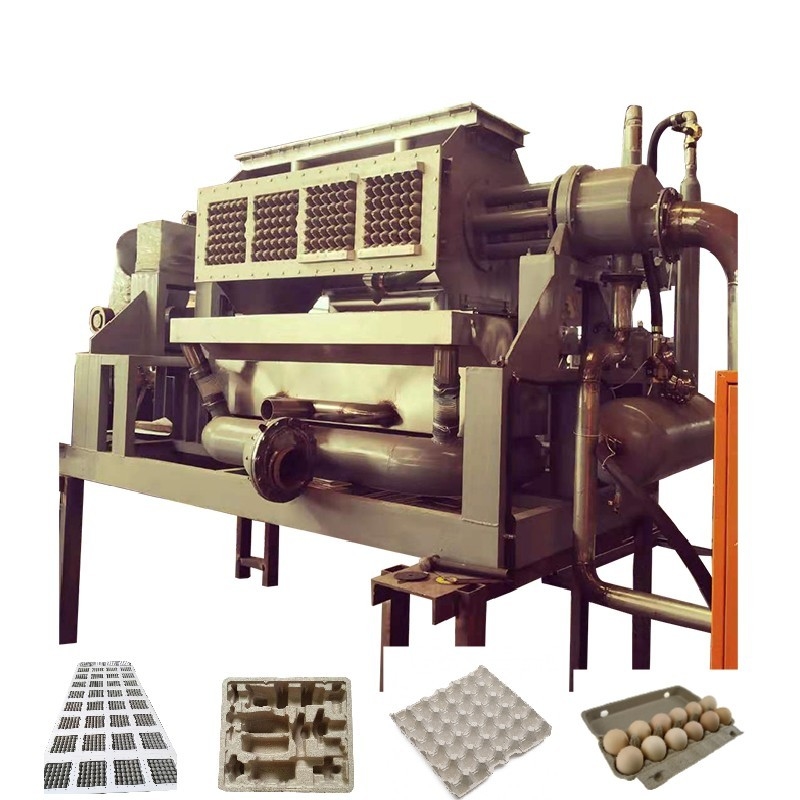

Pulping System

The first step in the pulping system is to put the raw material and water into the hydraulic pulper. After being mixed for 10-20 minutes, the resulting paper pulp is transferred to the slurry pool by the pulp pump. The pulp pond beater then mixes the pulp concentration, and the pulp pump transfers the pulp into the forming machine.

Molding System

The molding machine is responsible for absorbing the pulp into the molding mold. This is achieved through the suction of the vacuum system. The excess water is absorbed into the gas-water separation tank, and then the water is pumped to the tank for storage. The molding mold absorbs the pulp and forms it. The transfer mold then takes out the finished product and sends it to the drying tray inside the dryer oven.

Drying System

The drying system makes use of various combustible liquids and gases, such as natural gas, diesel, and liquefied petroleum gas, as a heat source. Industrial transmission chains are utilized to drive the net plate transmission, which runs in the drying line.

Packing

The products are packaged in waterproof materials and conform to international export standards. They can be packed in 20ft, 40ft, or 40hp containers. Equipment fittings, electric motors, and power cabinets are packed in wooden cases or iron boxes. Other equipment is packed in color-striped plastic cloth, or as per the customer's requirements.

Terms of Delivery

The latest date of shipment is 15-20 working days after receipt of prepayment. Payment terms are 30% advance payment by TT or 70% before delivery of goods. Alternatively, 100% payment can be made by L/C at sight against shipping documents.

Applications:

Paper Egg Trays

Paper egg trays are an essential end product of egg tray plant. These trays are designed to provide a strong and protective shell for eggs during their transportation and storage. Typically, an egg tray has 30 holes. However, by simply changing the mould, the machine can be used to create egg trays with 6, 10, 12, 15, 18, or 24 holes, as well as egg cartons, apple trays, shoe trays, seedling trays and more.

The raw materials required to create egg trays include: original wood pulp, craft paper, A4 paper, paper box products, old newspapers, old books, and other kinds of recycled papers. By utilizing these materials and the appropriate machinery, the process of creating egg trays becomes a cost-effective and eco-friendly process.

| Egg Tray Mold Quantity |

32pcs(4*8) |

| Raw material |

Waste paper |

| Egg tray Capacity |

3000-4000pcs/hour |

| Net weight per piece (gram) |

70g-75g |

| Waste paper consumption |

225kg / hour |

| Water Consumption |

0.6ton / hour |

| Natural Gas Consumption of Dryer |

80cbm/h |

| Worker requirement |

8-10workers |

| Power Requirement |

Without dryer |

100KW |

| With dryer |

150KW |

| Area of workshop |

Without dryer |

More than 250 M² |

| With dryer |

More than 520M² |

| Container Requirement |

Without dryer |

40ft*1 |

| With dryer |

40ft*5 |

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client's plant.

3. The above specification is for reference only, due to continuous technology development, data will be updated from time to time.

4. Pulp Molding Equipment are non-standard equipment, we are able to provide customized solution according to specific requirements from customer.

5. Welcome to contact us anytime, our professional team will provide more effective help and supports for you. |

Support and Services:

The Rotary Egg Tray Machine is designed to produce high-quality egg trays with varying capacities. Our product technical support and services include:

- Installation guidance and support

- Training for machine operation and maintenance

- Regular maintenance and repair services

- Supply of spare parts and accessories

- Technical assistance for production optimization

We are committed to ensuring that our customers receive the best technical support and services for their Rotary Egg Tray Machine. Contact us for more information.

Packing and Shipping:

Product Packaging:

The Rotary Egg Tray Machine will be packaged in a sturdy wooden crate to ensure safe transport. The crate will be properly sealed to prevent any damage to the machine during shipping.

Shipping:

The Rotary Egg Tray Machine will be shipped via sea or air freight, depending on the customer's preference and location. We will work with reputable shipping companies to ensure timely and secure delivery of the product.

FAQ:

Q: What is the brand name of this egg tray machine?

A: The brand name of this egg tray machine is WANYOU.

Q: Where is this egg tray machine manufactured?

A: This egg tray machine is manufactured in Jinan, Shandong.

Q: What is the minimum order quantity for this egg tray machine?

A: The minimum order quantity for this egg tray machine is 1 set.

Q: What is the price range for this egg tray machine?

A: The price range for this egg tray machine is between 6500usd-18000usd.

Q: How is this egg tray machine packaged for shipping?

A: This egg tray machine is packaged with plastic films for shipping.

Q: What is the delivery time for this egg tray machine?

A: The delivery time for this egg tray machine depends on the order quantity and specific requirements. Please contact us for more information.

Q: What are the payment terms for this egg tray machine?

A: The payment terms for this egg tray machine are TT (Telegraphic Transfer).

Q: What is the supply ability for this egg tray machine?

A: The supply ability for this egg tray machine is 1 set per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!