Product Description:

Pulping System

To begin the paper manufacturing process, the raw material and water are first put into the hydraulic pulper. After mixing for 10-20 minutes, the paper pulp is obtained. The finished paper pulp is then transferred into the slurry pool by the pulp pump. The pulp pond beater mixes the pulp concentration before transferring it into the forming machine by the pulp pump.

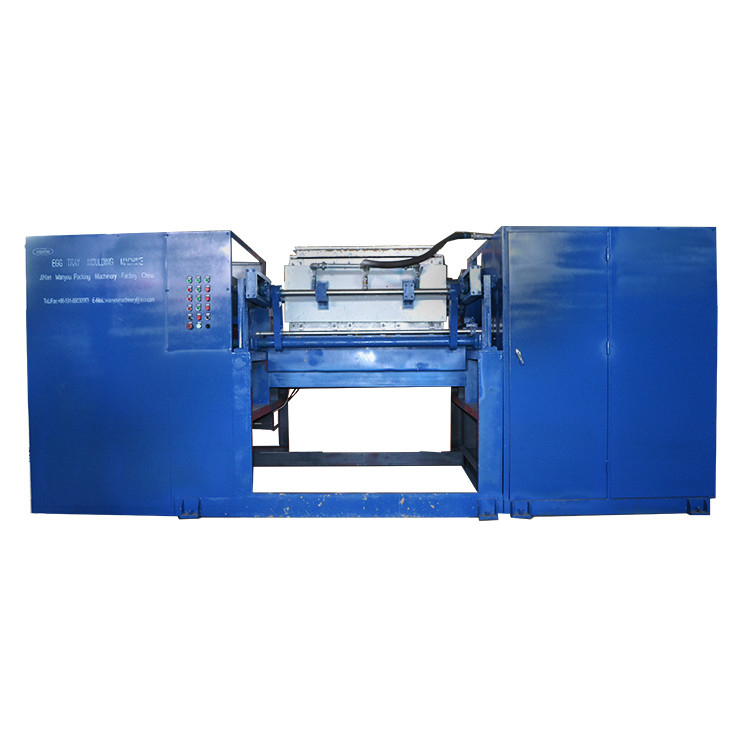

Molding System

The molding machine is used to absorb the pulp into the molding mold. The vacuum system absorbs the excess water and transfers it into the gas-water separation tank. The water is then pumped to the tank for storage. The molding mold absorbs the pulp and forms it, and the transfer mold takes out the finished product and sends it to the drying tray inside the dryer oven.

Drying System

The drying system uses natural gas, diesel, liquefied petroleum gas, and other combustion liquids and gases as the heat source. The transmission mode of the system uses industrial transmission chain to drive the net plate transmission, which runs in the drying line.

Packaging

The finished products are packed using waterproof packaging and follow the international export standard by 20ft, 40ft, and 40hp containers. The equipment fittings, electric motor and power cabinet will be packed in a wooden case or iron box while other equipment will be packed by color-stripes plastic cloth. Customers may request other packaging requirements.

Terms of Delivery

The latest date of shipment time is 15-20 working days after receipt of prepayment. Payment terms include 30% advance payment by TT, 70% before delivery of goods. Alternatively, customers may choose to pay 100% by L/C at sight against shipping documents.

Applications:

At the end of the production process in egg tray plant, the paper egg trays are formed. These trays serve as excellent protective shells for eggs during transportation and storage. The standard egg tray often contains 30 holes to hold individual eggs securely in place.

With a simple change of moulds, the machine used in the production of egg trays can make not only the standard 30 hole trays, but also trays with 6, 10, 12, 15, 18, and 24 holes, as well as egg cartons, apple trays, shoe trays, seedling trays, and more. This versatility in manufacturing makes the production process highly efficient and flexible.

Various types of recycled paper, such as original wood pulp, craft paper, A4 paper, paper boxes, old newspaper, old books, and so on are the raw materials utilized in the production process of egg trays. These materials effectively ensure that the production process is eco-friendly and cost-effective.

Technical Parameters:

| Model |

Capacity |

Forming machine |

Drying system |

Workshop space |

Rated power |

| WY-1500S |

1500-2000pcs/hr |

3molds *4faces |

Single-Layer Metal |

55m*10m*6m |

130KW |

| Rotary type |

| WY-1500M |

1500-2000pcs/hr |

3molds *4faces |

4 Layers |

35m*10m*6m |

120KW |

| Rotary type |

Metal |

| WY-2000S |

2000-2500pcs/hr |

4molds *4faces |

Single-Layer Metal |

60m*10m*6m |

165KW |

| Rotary type |

| WY-2000M |

2000-2500pcs/hr |

4molds *4faces |

4 Layers |

40m*10m*6m |

145KW |

| Rotary type |

Metal |

| WY-3000S |

3000pcs/hr |

3molds *8faces |

Single-Layer Metal |

65m*15m*6m |

209KW |

| Rotary type |

| WY-3000M |

3000pcs/hr |

3molds *8faces |

4Layers |

50m*15m*6m |

189KW |

| Rotary type |

Metal |

| WY-4000S |

4000pcs/hr |

4molds *8faces |

Single-Layer Metal |

75m*15m*6m |

239KW |

| Rotary type |

| WY-4000M |

4000pcs/hr |

4molds *8faces |

4 Layers |

50m*15m*6m |

223KW |

| Rotary type |

Metal |

| WY-5000S |

5000pcs/hr |

5molds *8faces |

Single-Layer Metal |

70m*15m*6m |

298KW |

| Rotary type |

| WY-5000M |

5000pcs/hr |

5molds *8faces |

4 Layers |

55m*15m*6m |

273KW |

| Rotary type |

Metal |

| WY-6000S |

6000pcs/hr |

6molds *8faces |

Single-Layer Metal |

80m*15m*6m |

365KW |

| Rotary type |

| WY-6000M |

6000pcs/hr |

6molds *8faces |

4 Layers |

55m*15m*6m |

326KW |

| Rotary type |

Metal |

Support and Services:

Our Rotary Egg Tray Machine is designed to produce high-quality egg trays with various capacities ranging from 30 to 6000 pieces per hour. Our technical support team is available to assist you in setting up and maintaining the machine to ensure optimal performance and longevity.

We also offer a range of services, including:

- Installation and commissioning of the machine

- Training for operators and maintenance personnel

- Supply of spare parts and accessories

- Machine upgrades and customization

- 24/7 technical support and troubleshooting

Our goal is to provide you with reliable and efficient egg tray production solutions to meet your specific needs. Contact us to learn more about our Rotary Egg Tray Machine and the services we offer.

Packing and Shipping:

Product Packaging:

- The Rotary Egg Tray Machine will be securely packed in a wooden case to ensure safe transportation.

- All necessary accessories and instructions will be included.

Shipping:

- The product will be shipped by sea or by air, depending on the customer's preference.

- Shipping time will vary depending on the destination and shipping method chosen by the customer.

- The customer will be provided with a tracking number to monitor the status of their shipment.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is WANYOU.

Q: What is the model number of this product?

A: The model number of this product is WY-1.

Q: Where is this product manufactured?

A: This product is manufactured in Jinan, Shandong.

Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set.

Q: How much does this product cost?

A: The price of this product ranges from 6500usd to 18000usd.

Q: What is the packaging of this product?

A: The packaging of this product is plastic films.

Q: How long does it take to deliver this product?

A: The delivery time of this product depends on the location and quantity of the order.

Q: What are the payment terms for this product?

A: The payment terms for this product are TT.

Q: What is the supply ability of this product?

A: The supply ability of this product is 1 set per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!