Product Description:

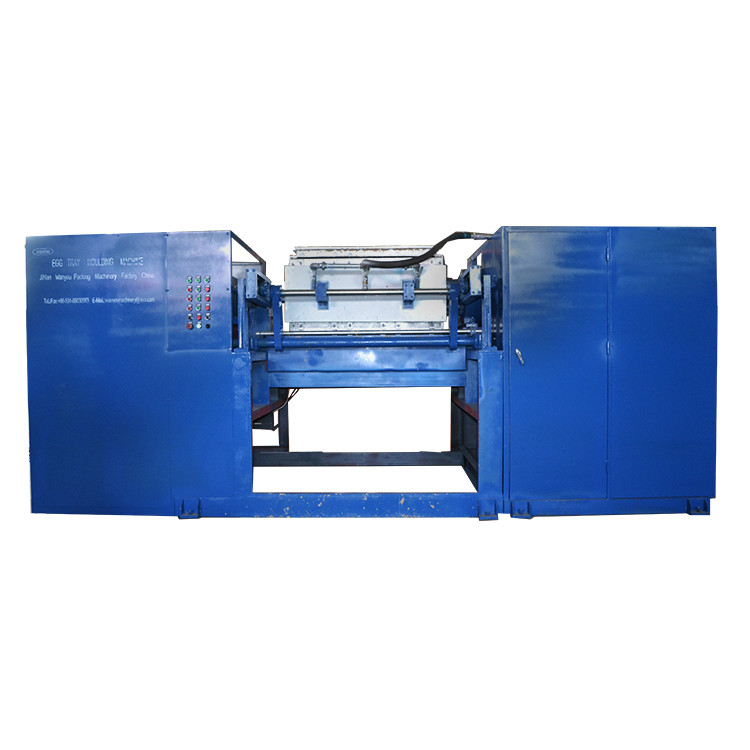

Rotary Egg Tray Machine

Key Words: Pulp Molding Egg Tray Machine, Automatic Egg Tray Making Line, Paper Egg Tray Making Machine, Egg Tray Forming Machine

Color: Customized

Product Type: Rotary Egg Tray Machine

Power: 380V/50Hz

Design Speed: Customized

The Rotary Egg Tray Machine is an essential piece of equipment for any egg production facility. It is designed to efficiently and effectively produce high-quality egg trays, using a pulp molding process. This machine is capable of handling a large volume of egg trays, making it ideal for large-scale production.

Automatic Egg Tray Making Line: The Rotary Egg Tray Machine is a part of a fully automatic egg tray making line. This means that the entire process, from pulp preparation to tray forming and drying, is automated, resulting in a more efficient and streamlined production process. This also reduces the labor and time required for production, making it a cost-effective option for egg tray production.

Paper Egg Tray Making Machine: The Rotary Egg Tray Machine is specifically designed to use paper pulp as its raw material. This makes it an environmentally friendly option, as it uses recyclable materials to produce the egg trays. The machine can handle a wide range of paper materials, including waste paper, cardboard, and other paper products, making it a versatile choice for egg tray production.

Egg Tray Forming Machine: The Rotary Egg Tray Machine features a rotary design, which allows for the continuous production of egg trays. The pulp molding process involves the use of molds to shape the paper pulp into the desired tray shape. The machine can produce various tray sizes and shapes, including 30-cell, 6-cell, and 10-cell egg trays, to meet different customer needs.

Pulp Molding Machine: The Rotary Egg Tray Machine uses a pulp molding process, which involves mixing paper pulp with water and then molding it into the desired shape. This process ensures that the egg trays produced are strong, durable, and of high quality. The machine also has a drying system that removes excess moisture from the trays, ensuring they are ready for use.

Overall, the Rotary Egg Tray Machine is a reliable, efficient, and cost-effective option for egg tray production. Its customizable design speed and ability to handle a variety of paper materials make it a versatile choice for any egg production facility. With its automatic egg tray making line, this machine is sure to increase productivity and profitability for any business.

| Egg Tray Mold Quantity |

12pcs(3pcs*4) |

16pcs(4pcs*4) |

24pcs(3pcs*8) |

32pcs(4pcs*8) |

| Raw material |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

| Egg tray Capacity(pcs/hour) |

2000 |

2500 |

3000 |

4000 |

| Net weight per piece (gram) |

70-75 |

70-75 |

70-75 |

70-75 |

| Waste paper consumption |

150kg/ h |

150kg/h |

188kg/h |

225kg / hour |

| Water Consumption |

0.45ton / h |

0.6ton/h |

0.68ton/h |

0.9ton / h |

| Natural Gas Consumption of Dryer |

75cbm/h |

90cbm/h |

110cbm/h |

120cbm/h |

| Boiler model (natural gas fuel Kcal) |

800*103 |

1000*103 |

1200*103 |

1500*103 |

| Worker requirement |

5-7workers |

5-7workers |

8-10workers |

8-10workers |

| Power Requirement |

Without dryer |

70KW |

80KW |

100KW |

100KW |

| With dryer |

100KW |

120KW |

130KW |

150KW |

| Area of workshop |

Without dryer |

More than

200 M² |

More than 200 M² |

More than 250 M² |

More than 250 M² |

| With dryer |

More than 400M²

Dryer18M |

More than 400M²

Dryer20M |

More than 520M² dryer30M |

More than 520M²

Dryer32M |

| Container Requirement |

Without dryer |

40ft*1 |

40ft*1 |

40ft*1 |

40ft*1 |

| With dryer |

40ft*4 |

40ft*4 |

40ft*5 |

40ft*5 |

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client's plant.

3. The above specification is for reference only, due to continuous technology development, data will be updated from time to time.

4. Pulp Molding Equipment are non-standard equipment, we are able to provide customized solution according to specific requirements from customer.

5. Welcome to contact us anytime, our professional team will provide more effective help and supports for you. |

Applications:

Rotary Egg Tray Machine - WANYOU

Rotary Egg Tray Machine, also known as Egg Tray Shaping Machine, is a high-quality and efficient equipment used for producing egg trays, egg cartons, and other paper pulp molded products. It is produced by WANYOU, a leading manufacturer of paper tray machines, with the model number WY-1. Our factory is located in Jinan, Shandong, and we have a minimum order quantity of 1 set.

Application and Scenario

The Rotary Egg Tray Machine is widely used in various industries such as agriculture, food packaging, and logistics. It is especially suitable for egg tray and egg carton production, making it an essential equipment for egg farms, egg packaging companies, and transportation companies.

In an egg farm, the Rotary Egg Tray Machine can be used to produce egg trays to protect the eggs during transportation and storage. It can also be used to produce egg cartons for commercial sales, providing a safe and hygienic packaging solution for the eggs.

In a food packaging company, the machine can be used to produce egg cartons for supermarkets and grocery stores, ensuring the quality and safety of the eggs for consumers. It can also be used to produce other paper pulp molded products such as fruit trays, cup holders, and shoe inserts, expanding its application in the food industry.

In a logistics company, the Rotary Egg Tray Machine can be used to produce egg trays for packaging and transporting eggs. The trays are designed to fit standard egg boxes, making it easier and more efficient to handle and transport the eggs.

Product Attributes

- Brand Name: WANYOU

- Model Number: WY-1

- Place of Origin: Jinan, Shandong

- Minimum Order Quantity: 1 set

- Price: 6500usd-18000usd

- Packaging Details: plastic films

- Delivery Time: depends

- Payment Terms: TT

- Supply Ability: 1set/month

- Raw Material: Recycled Paper

- Type: Rotary Drum, Produce By Sample

- Usage: Paper Tray Machine

- Product Type: Rotary Egg Tray Machine

- Economic Speed: 6s/times

Features and Advantages

The Rotary Egg Tray Machine is designed with advanced technology and high-quality materials, ensuring its durability and efficiency. Some of its main features and advantages include:

- Rotary Drum Structure: The machine is equipped with a rotary drum, which can continuously rotate and produce large quantities of egg trays in a short amount of time.

- Produce By Sample: The machine is highly customizable and can produce different types and sizes of egg trays according to the sample provided by the customer.

- Fast and Efficient: With an economic speed of 6s/times, the machine can produce up to 6000 pieces of egg trays per hour, greatly improving production efficiency.

- Environmentally Friendly: The machine uses recycled paper as raw material, making it an eco-friendly and sustainable option for paper pulp molded product production.

- Easy Operation: The machine is designed with a user-friendly interface and requires minimal training to operate, making it suitable for both experienced and novice operators.

Overall, the Rotary Egg Tray Machine by WANYOU is a reliable and cost-effective solution for egg tray and egg carton production. With its high efficiency, customizable options, and environmentally friendly features, it is an essential equipment for various industries.

Customization:

Rotary Egg Tray Machine - Customized Service

Brand Name: WANYOU

Model Number: WY-1

Place of Origin: Jinan, Shandong

Minimum Order Quantity: 1 set

Price: 6500usd-18000usd

Packaging Details: plastic films

Delivery Time: depends

Payment Terms: TT

Supply Ability: 1set/month

Waste Paper Consumption: 150kg/h-450kg/h

Machine Type: Rotary Type

Product Type: Rotary Egg Tray Machine

Type: Rotary Drum, Produce By Sample

Usage: Paper Tray Machine

Customized Service: Our Rotary Egg Tray Machine can be customized according to your specific requirements. We offer a variety of options for the machine size, production capacity, and other features to meet your unique needs. Our experienced engineers will work closely with you to design and manufacture a machine that fits your production process perfectly.

Rotary forming egg tray molding machine: Our machine uses a rotary forming process to produce high-quality egg trays. The rotary drum ensures uniform and smooth shaping of the trays, reducing the risk of breakage and increasing production efficiency.

Egg tray shaping machine: Our egg tray shaping machine is designed to shape the pulp into egg trays of various sizes and shapes. It is equipped with advanced technology and precise molds to ensure consistent and accurate shaping.

Pulp molding egg tray machine: Our machine uses recycled waste paper as raw material, making it an environmentally friendly and sustainable production option. It is an efficient and cost-effective solution for producing egg trays.

Choose WANYOU for your Rotary Egg Tray Machine needs and let us provide you with top-quality customized service for your business. Contact us today for more information and a personalized quote.

Packing and Shipping:

Packaging and Shipping

The Rotary Egg Tray Machine is carefully packaged to ensure safe delivery to our customers. The machine is first wrapped in protective materials, such as bubble wrap or foam, to prevent any damage during shipping.

Next, the machine is placed in a sturdy wooden crate and securely fastened with straps and nails. This provides additional protection during transportation.

The machine's important components, such as the motor and control panel, are also carefully packaged and placed in a separate box to prevent any potential damage.

After packaging, the machine is loaded onto a transportation vehicle and shipped to the designated address. We work with reliable shipping companies to ensure timely delivery of our products to our customers.

Upon arrival, the machine will be unloaded and inspected to ensure that it has arrived in perfect condition. Our team will also provide assistance with assembly and installation, if needed.

We are committed to providing our customers with high-quality products and reliable shipping services to ensure a smooth and satisfactory experience.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is WANYOU.

- Q: What is the model number of this product?

A: The model number of this product is WY-1.

- Q: Where is this product manufactured?

A: This product is manufactured in Jinan, Shandong.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set.

- Q: What is the price range for this product?

A: The price for this product ranges from 6500 USD to 18000 USD.

- Q: How is this product packaged?

A: This product is packaged with plastic films.

- Q: What is the estimated delivery time for this product?

A: The delivery time for this product depends on various factors.

- Q: What are the payment terms for this product?

A: The payment terms for this product is TT (telegraphic transfer).

- Q: What is the supply ability of this product?

A: The supply ability for this product is 1 set per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!