Product Description:

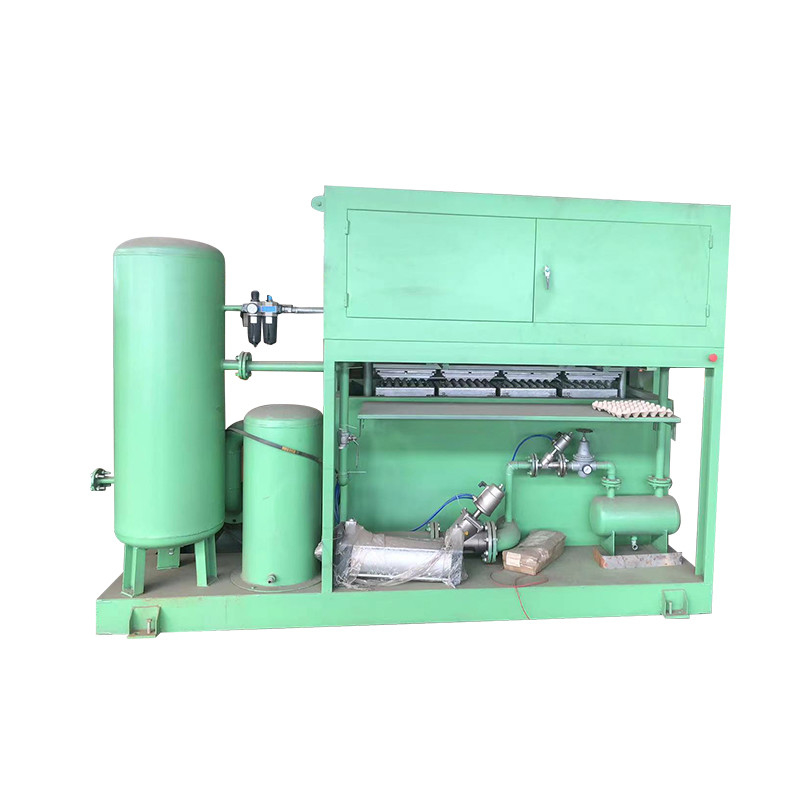

The Paper Pulp Molding Machine is an ideal equipment for the production of paper pulp trays. It has a capacity of 700pcs-6000pcs/h, and it can produce paper egg trays, apple trays, fruit trays, coffee cup holder trays, shoe stretchers and other paper pulp trays. With its automatic operation, it ensures a high efficiency and easy operation. Moreover, it comes with 1 year warranty and online technical support, providing users with a reliable and worry-free after-sales service.

Pulping System

1. Put the raw material and water into the hydraulic pulper, you will get the paper pulp after mixed 10-20 minutes.

2. Pulp pump will transfer the finished paper pulp into the slurry pool.

3. The pulp pond beater will mix the pulp concentration.

4. The pulp pump will transfer the pulp into forming machine.

Molding System

1. The molding machine is to adsorb the pulp to the molding mold, adsorb the pulp to the molding mold through the suction of the vacuum system to absorb the excess water into the gas-water separation tank, and then pump the water to the tank for storage.

2. The molding mold adsorbs the pulp and then forms it. and then the transfer mold takes out the finished product and sends it to the they drying tray.

Drying System

1.Heat source: natural gas, diesel, liquefied petroleum gas and other combustion liquids and gases.The transmission mode adopts industrial transmission chain to drive the net plate transmission, which runs in the drying line.

Packing

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Techinical Data of Pulp molding machine

| Egg Tray Mold Quantity |

2pcs |

3pcs |

4pcs |

12pcs(3pcs*4) |

16pcs(4pcs*4) |

32pcs(4pcs*8) |

| Raw material |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

| Egg tray Capacity(pcs/hour) |

700 |

1000 |

1300 |

2000 |

2500 |

4000 |

| Net weight per piece (gram) |

70-75 |

70-75 |

70-75 |

70-75 |

70-75 |

70-75 |

| Waste paper consumption |

0.06ton / h |

0.1ton / h |

0.13ton / h |

150kg/ h |

150kg/h |

225kg / hour |

| Water Consumption |

0.15ton/h |

0.22ton / h |

0.3ton / h |

0.45ton / h |

0.6ton/h |

0.9ton / h |

| Natural Gas Consumption of Dryer |

25cbm/h |

45cbm/h |

60cbm/h |

75cbm/h |

90cbm/h |

120cbm/h |

| Boiler model (natural gas fuel Kcal) |

300*103 |

450* |

600*103 |

800*103 |

1000*103 |

1500*103 |

| Worker requirement |

3-4workers |

4-6workers |

4-6workers |

5-7workers |

5-7workers |

8-10workers |

| Power Requirement |

Without dryer |

30KW |

40KW |

45KW |

70KW |

80KW |

100KW |

| With dryer |

45KW |

60KW |

65KW |

100KW |

120KW |

150KW |

| Area of workshop |

Without dryer |

More than 100 M² |

More than 120 M² |

More than 150 M² |

More than

200 M² |

More than 200 M² |

More than 250 M² |

| With dryer |

More than 240M²

dryer-16M |

More than300M²

Dryer-16M |

More than 320 M²

dryer-18M |

More than 400M²

Dryer18M |

More than 400M²

Dryer20M |

More than 520M²

Dryer32M |

| Container Requirement |

Without dryer |

20ft*1 |

40ft*1 |

40ft*1 |

40ft*1 |

40ft*1 |

40ft*1 |

| With dryer |

40ft*2+20ft*1 |

40ft*3 |

40ft*3 |

40ft*4 |

40ft*4 |

40ft*5 |

Remarks:

1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g).

2. Workshop size is for reference only and could be adjusted according to actual size of client's plant.

3. The above specification is for reference only, due to continuous technology development, data will be updated from time to time.

4. Pulp Molding Equipment are non-standard equipment, we are able to provide customized solution according to specific requirements from customer.

5. Welcome to contact us anytime, our professional team will provide more effective help and supports for you. |

Applications:

The WANYOU Paper Pulp Molding Machine (WY-1) is a versatile and reliable paper pulp tray shaping machine that can be used in a variety of different applications and scenarios. It is designed to be used for creating paper egg trays, apple trays, fruit trays, coffee cup holders, shoe stretchers, and more. With its low power consumption and high capacity of 700-6000 pieces per hour, it is ideal for production lines. The machine is produced in Jinan, Shandong, and the minimum order quantity is 1 set. It is priced at 6500-18000 USD, and it is typically packaged in plastic films. Delivery times depend on the order, and payment terms are usually by TT. The Supply Ability is 1 set per month. It comes with a voltage of 220V/380V.

This multi-purpose Paper Pulp tray Shaping Machine is a great choice for businesses who need to produce paper egg trays, apple trays, fruit trays, coffee cup holders, shoe stretchers, and more. It is easy to use and provides high rates of production. With its low power consumption and high capacity of 700-6000 pieces per hour, it is efficient and cost-effective. The WANYOU Paper Pulp Molding Machine (WY-1) is the perfect choice for businesses who need to produce Paper Pulp tray Molding Equipment and Paper Pulp tray Fabricating Machine.

Customization:

Customized Service for WANYOU Paper Pulp Molding Machine

- Brand Name: WANYOU

- Model Number: WY-1

- Place of Origin: Jinan, Shandong

- Minimum Order Quantity: 1 set

- Price: 6500usd-18000usd

- Packaging Details: plastic films

- Delivery Time: depends

- Payment Terms: TT

- Supply Ability: 1set/month

- After-sale Service: Online Technical Support

- Warranty: 1 Year

- Application: Paper Pulp Molding

- Capacity: 700pcs-6000pcs/h

- Control System: PLC

The WANYOU Paper Pulp Molding Machine is designed for paper pulp tray moulding, paper pulp tray casting and paper pulp tray production. It is equipped with a PLC control system that can offer a capacity of 700-6000pcs/h. It is reliable and easy to use, and comes with a 1 year warranty and online technical support for after-sale service. We offer competitive prices ranging from 6500usd-18000usd and delivery time depends on the order quantity.

Support and Services:

Technical Support and Service for Paper Pulp Molding Machine

We provide technical support and service for our Paper Pulp Molding Machine. Our support team is available to answer any questions you have regarding the use and maintenance of our product. We have a wide variety of services available, including:

- Installation and setup of the machine

- Technical troubleshooting

- Regular maintenance and inspections

- Repair and replacement of parts

- Technical advice and guidance

We are committed to providing excellent customer service and technical support to ensure that our customers have the best experience possible. If you have any questions or need assistance, please do not hesitate to contact us.

Packing and Shipping:

Paper Pulp Molding Machine should be packed and shipped with utmost care to ensure that it is not damaged during shipping. The following steps should be taken to ensure proper packaging and shipping:

- The machine should be covered with bubble wrap, and then placed in a strong cardboard box.

- The box should be properly sealed with packing tape.

- The box should be labeled with the appropriate shipping information.

- The box should be placed in a larger box with adequate cushioning material to prevent any possible damage.

- The larger box should be properly sealed with packing tape.

- The larger box should be labeled with the appropriate shipping information.

- The larger box should be picked up by the carrier.

FAQ:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!