CE Approved Paper Egg Tray Making Machine Egg Carton Machine Low Noise

Working theroy of our machine is as follows:

The Egg Tray Molding System consists of various equipment and dies.

The wet forming section consists of a series of wire screen covered wet forming dies mounted on a molding drum, and a matching set of transfer dies mounted on a transfer mechanism.

The egg tray forming die is made up of rigid corrosive resistant metal or ABS engineering plastic and consists of many component parts that are drilled with small drainage holes and covered by prior to formed stainless steel screens.

The forming die, mounted on the molding drum is rotated at a uniform speed, immersing it in a taper flow vat containing the pulp slurry of about 1% consistency of fibers in recycled water. A vacuum system attracts the fibers to deposit on the forming die screens as the suspending recycle water is drawn through the screen and drainage holes.

Paper Egg Tray Manufacturing Process:

1.Pulp Making Process:

♦Put the waste paper into the hydraulic pulper. After about 40 minutes’ high consistency mixing, the waste paper will be made into rough pulp. The proportion is 1(paper) :3(water).

♦Then the rough pulp will flow into the homogenization pool. The rough pulp will be refined further by the pulp beater in the homogenization pool.

♦The appropriate concentration of the pulp will flow into the finished pulp to supply paper pulp to the forming machine.

2.Molding Process:

♦By pulp pump, the finished pulp will be transported into the paper tray forming machine.

♦Under the suction power of vacuum pump, the pump will be adsorbed up on molds to form egg tray.

♦Under the blowing force of air compressor, the formed egg tray will drop off from molds.

3.Drying Process:

♦In the egg tray drying process, the extra water component in the wet egg trays can be evaporated. Drying is the essential process. After drying, paper egg trays are not easy for deformation and broken.

All the machine is in computer control, which is also very easy to operate and donnot need high level knowledge requirement for the workers.

Our Paper Egg Tray Machine saves production cost, and saves space. it is quitely used by small medium enterprises.

Our machine can turn your waste paper and books into Money!

=

This production line is suitable for the following products:

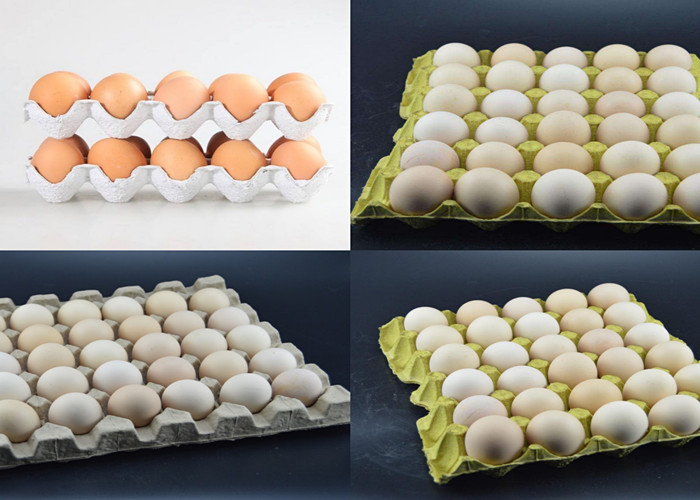

Egg tray(30-egg) Egg box/egg carton(6-egg, 10-egg, 12-egg, 6+6-egg, 15-egg, 18-egg and etc)

Fruit tray (for apple,tomato, pear and etc) Cup carrier(4 pack and 2 pack) Seeding tray and bottle trays.

Some medical-care products and fixed shape(the design doesn't change frequently) pulp molding products with large quantity.

Tech data of egg tray machine

| Egg Tray Mold Quantity |

3pcs |

| Raw material |

Waste paper |

| Egg tray Capacity |

1000pcs/hour |

| Net weight per piece (gram) |

70g-75g |

| Waste paper consumption |

75kg / hour |

| Water Consumption |

0.15ton / hour |

| Natural Gas Consumption of Dryer |

35cbm/h |

| Worker requirement |

4-6workers |

| Machine Length |

7m-28m |

| Machine weight |

8-30tons |

| Power Requirement |

Without dryer |

40KW |

| With dryer |

60KW |

| Area of workshop |

Without dryer |

More than 120 M² |

| With dryer, dryer-18m |

More than300M² |

| Container Requirement |

Without dryer |

40ft*1 |

| With dryer |

40ft*2+20ft*1 |

| Remarks: 1. The egg tray Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g). 2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant. |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 35 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE or 30% TT Deposit + 70% LC |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

FAQ

(1). What kind of material we can use as the raw material?

Any kind of waste paper like old newspaper,magazines,books,A4 paper, corrugated cartons, paperboard etc.

(2). What kind of Fuel can be used for the whole production line?

Coal, natural gas, and dieseal oil.

(3). What kind of products can be made by this machine?

All paperpackage such as paper egg tray, egg carton,egg box, fruit tray, bottle tray, cup tray, consumer product package, medical disposable container etc.

(4). Are you a manufacturer or a trading company?

Yes, our company has been fabricating pulp molding machine since 2000. We are one of the

most important pulp molding machine maufacturers in the world, and we are famous pulp

molding machine manufacturer in China, providing high quality and production capacity pulp molding

machinery at reasonable prices to the world.

(5). What capacity egg tray machine can you supply?

At the moment, we can supply 350 pcs/h, 700, 1000, 1300, 1800, 2000, 2400, 3000pcs/h capcaity egg tray

machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!