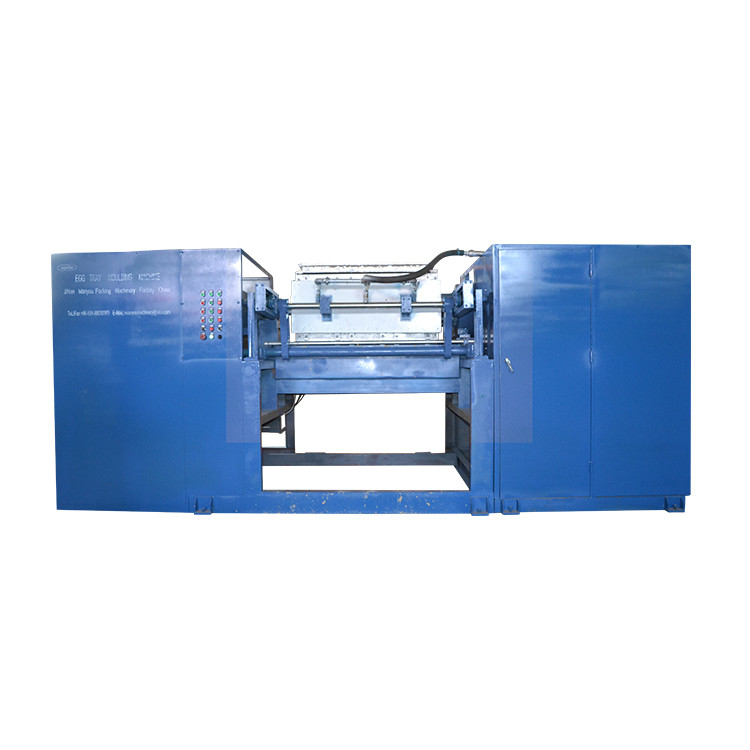

Rotary Forming Type Waste Paper Egg Tray Making Machine Egg Tray Making Plant Egg Packing

Rotary Forming Type Waste Paper Egg Tray Making Machine Egg Tray Making Plant Egg Packing

It can make many simple shape and large quantity demand egg trays, apple trays, egg cartons, egg boxes, wine trays, shoe trays, etc..using waste paper as raw material.

Pulp molding products are one kind of new packing material. This is a new buzz in recent years. Pulp molding machinery is a type of environmentally friendly equipment that mixes waste paper and water as raw material. The pulp moulding machine cost is low and you don’t need to spend too much money. The pulp molding machines have great develop prospect on the market.

Paper egg tray is considered as a sustainable packaging material. It is produced from recycled materials, and can be recycled again after its useful life-cycle. With the wide application of paper egg trays, the paper egg tray making machine is becoming the hot sales machine on the markets.

The egg tray machine has Semi automatic and automatic and fully automatic production process. The unique characteristic of the automatic machine is that it has automatic egg tray dryer. With this kind of machine, you can dry the semi-finished wet egg trays automatically.

1. Pulping System:

Put the waster paper into the hydrapulper , the paper and water will mix in hydrapulper ,then go to the refiner machine ,refiner machine make the pulp more small and uniform ,then the pulp pump absorb the pulp to the pulp pool .after the second mix in the pulp pool ,the pulp will go to the form machine pulp tank .

2. Forming System :

The vacuum pump will offer the vacuum to make the forming mould absorb the pulp from the pulp tank. One PLC cabinet will control the pulp absorb time ,the finished product will be shaped on the forming mould ,then the transfer mould transfer the products to the drying line ,the air compressor will give the air to blow the products ,then the products will drop down from the mould .Then the products is delivered to the drying line automatically; the water will go back to the water pool recycled.

3. Drying system: The formed Product Tray plate being delivered to Dryer, and come up to Completed Strong Product Tray plate The drying system is with one boiler. The drying system can use electricity, diesel, coal, natural gas as energy. Customers must first confirm which kind of energy they will use before our production. Our production line has Fully Automatic and Semi Automatic two types , both have computer control system.

For pulp molded 30-cell egg trays : first the worker will weight the raw material and put them into the conveyor. Then the pulping ,forming, drying and stacking will be finished automatically. After drying, the finished products will be packed by workers.

A hot pressing section should be added in the production of pulp molded egg box/carton(6-cell,10-cell,12-cell,6+6-cell,15-cell),fruit tray and cup carrier after drying because of shrinking.

The egg box/carton can be labelled or printed after hot pressing. These processes could be finsihed manually or automatically.

We have variety capacity egg tray machines from 350pcs/h to 2500pcs/h. We are OEM factory, we can manufacture the machine as per your requirement.

Our Paper Egg Tray Machine saves production cost, and saves space. it is quitely used by small medium enterprises.

Quick Detail

Condition: New

Product Type: Egg Tray Machine

Processing Type: Pulp Molding Machine

Place of Origin: Shandong, China (Mainland)

Brand Name: Wanyou

Voltage: 220-440V

Power(W): Different Machine Model

Dimension(L*W*H): 7m*2.2m*2.2m

Weight: 8 tons-15tons

Certification: CE & ISO

Warranty: 2 years

After-sales Service Provided: Engineers available to service machinery overseas

Capacity: 3000pcs/h

Color: As customer needs

Frequency: 50Hz-60Hz

Application: egg tray,fruit tray,bottle tray

Workshop required: 150-300㎡

Worker required: 5-6 persons

Fuel: Coal, Natural Gas, Disel, LPG and so on

Automation: Automatic and fully automatic

Keyword: Egg tray machine

This production line is suitable for the following products:

Egg tray(30-egg) Egg box/egg carton(6-egg, 10-egg, 12-egg, 6+6-egg, 15-egg, 18-egg and etc)

Fruit tray (for apple,tomato, pear and etc) Cup carrier(4 pack and 2 pack) Seeding tray and bottle trays.

Some medical-care products and fixed shape(the design doesn't change frequently) pulp molding products with large quantity.

Technical data

| Technical Parameters of the Egg Tray Machine |

| pulp system |

Hydra Pulper |

30KW |

Effective Power:25KW,material of tank and disc:carbonized steel ,material of screen plate:stainless steel , pulping consistency:3-4%.

|

| |

Mixer/Crusher |

1.5KW/h |

Stainless steel shaft and impeller,Mixing diameter:1200mm,match with pulp chest of 2 meters deepth,match with pulp chest of 2 meters deepth.not included support bracket.

|

| |

Vibration Screen |

3kw/h customized

Some type machine donnot need this equipment

|

Screen area:0.9m2 including protective casing.

|

| forming system |

8 faces Rotary forming machine |

40pcs forming molds and 5 pcs transfer molds and 5 pcs press molds

|

PLC control,stainless steel pulp tank,the surface of platens covered with stainless steel,the products should be transferred to a plate manually.The main electrical elements is Siemens brand. |

| |

Auto Drain System |

|

Match with Forming System include Air-water Separation Tank,Auto Drain Tank,Support,Check Valve, Electromagnetic Valve, Inductor,etc |

| |

Control Cabinet for Forming System

|

/ |

Control the forming machine.The main electrical elements is Germany brand. |

| drying system |

4-layer Drying Line |

16kw/h |

Effective length 100m, transfer speed adjustable. Fuel : Diesel oil/Nature gas/LPG

|

| |

Control Cabinet for Drying System

|

380v/50hz 440v/60hz |

Control the drying system.The main electrical elements is Taiwan brand.

|

| |

Burner |

|

Riello Brand |

| |

Boiler |

|

China Famous Brand |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 45 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE or 30% TT Deposit + 70% LC |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

Factory Introduction

Jinan Wanyou Packing Machinery Co.,Ltd is a famous packing machinery company which has a good mix of science, industry and trade.

It has been devoting to studying, developing, and manufacturing of packing machinery for more than ten years.

It absorbs advanced technology and industrial arts at home and abroad, and has studied and developed ZSJ series paper pulp molding plant, YS series paper carton automatic print fluting machine, BD series thin cutter paper slitter and paper carton series cutter chain.

These products are sold to many countries and areas, such as Algeria, Tunisia, Argentina, Vietnam, Russia, Uzbekistan, Nigeria, Taiwan and so on.

Don’t miss the chance of promoting the production efficiency of your company.

Welcome to contact us.

Dryer

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!