Pulp Molding Machine Egg Tray Making Machine Semi-automatic Type (Support Customize)

And this machine has following features:

1. capacity 350-6000pcs per hour

2. use waste paper as raw materials

3. machine including making pulp unit ,molding unit

4. computer control

Quick Detail

Condition: New

Product Type: Egg Tray Machine

Processing Type: Pulp Molding Machine

Place of Origin: Shandong, China (Mainland)

Brand Name: RUNLIANG

Voltage: 220-440V

Power(W): 28kw~50kw

Dimension(L*W*H): 2300mm*1950mm*1600mm

Weight: 4 tons-20tons

Certification: CE & ISO

Warranty: 2 years

After-sales Service Provided: Engineers available to service machinery overseas

Capacity: 350pcs/h -1300 pcs/h

Color: As customer needs

Frequency: 50Hz-60Hz

Application: egg tray,fruit tray,bottle tray

Workshop required: 50-180㎡

Worker required: 5-6 persons

Fuel: Coal, Natural Gas, Disel, LPG and so on

Automation: Semi-auto and fully automatic

Keyword: Egg tray machine

Paper Egg Tray Manufacturing Process:

1.Pulp Making Process:

♦Put the waste paper into the hydraulic pulper. After about 40 minutes’ high consistency mixing, the waste paper will be made into rough pulp. The proportion is 1(paper) :3(water).

♦Then the rough pulp will flow into the homogenization pool. The rough pulp will be refined further by the pulp beater in the homogenization pool.

♦The appropriate concentration of the pulp will flow into the finished pulp to supply paper pulp to the forming machine.

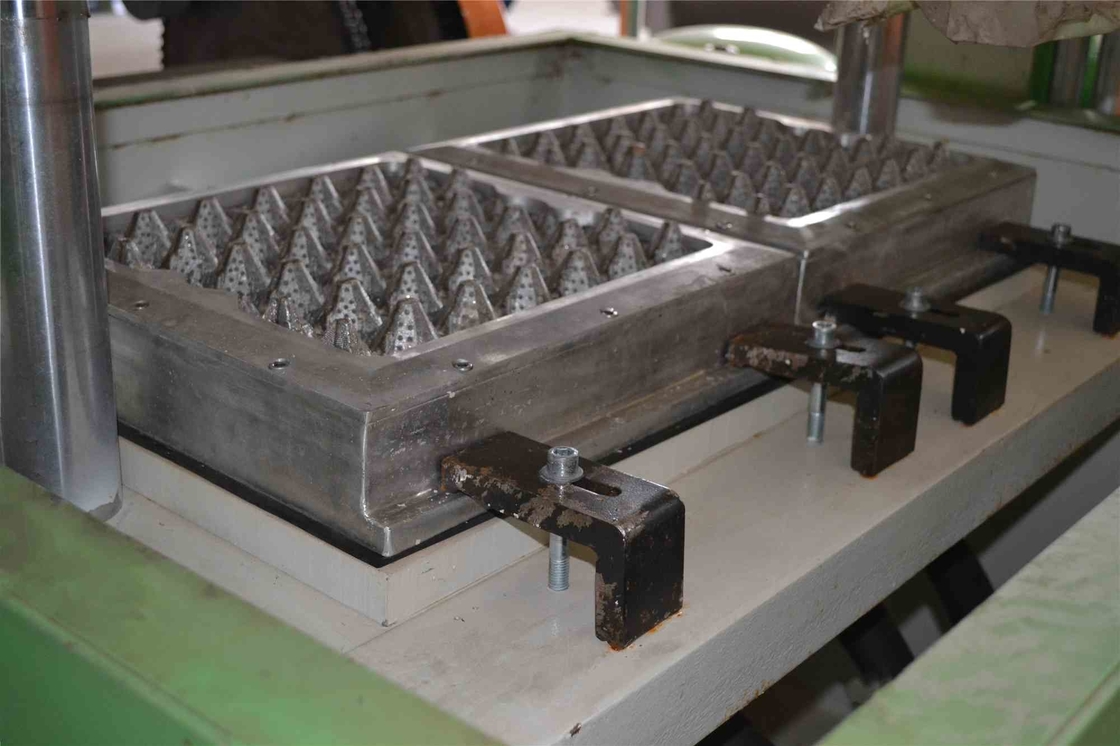

2.Molding Process:

♦By pulp pump, the finished pulp will be transported into the paper tray forming machine.

♦Under the suction power of vacuum pump, the pump will be adsorbed up on molds to form egg tray.

♦Under the blowing force of air compressor, the formed egg tray will drop off from molds.

3.Drying Process:

In the egg tray drying process, the extra water component in the wet egg trays can be evaporated. Drying is the essential process. After drying, paper egg trays are not easy for deformation and broken.

Technical data

| Egg Tray Mold Quantity |

1pcs |

2pcs |

3pcs |

4pcs |

| Raw material |

Waste paper |

Waste paper |

Waste paper |

Waste paper |

| Egg tray Capacity |

350pcs/hour |

700pcs/hour |

1000pcs/hour |

1300pcs/hour |

| Net weight per piece (gram) |

70g-75g |

70g-75g |

70g-75g |

70g-75g |

| Waste paper consumption |

0.025ton / hour |

0.06ton / hour |

0.1ton / hour |

0.13ton / hour |

| Water Consumption |

0.05ton / hour |

0.1ton/hour |

0.15ton / hour |

0.2ton / hour |

| Natural Gas Consumption of Dryer |

12cbm/h |

25cbm/h |

35cbm/h |

50cbm/h |

| Worker requirement |

2-3workers |

3-4workers |

4-6workers |

4-6workers |

| Power Requirement |

Without dryer |

20KW |

30KW |

40KW |

45KW |

| With dryer |

30KW |

45KW |

60KW |

65KW |

| Area of workshop |

Without dryer |

More than100M² |

More than 100 M² |

More than 120 M² |

More than 150 M² |

| With dryer |

More than200 M² |

More than 240 M² |

More than300M² |

More than 320 M² |

| Container Requirement |

Without dryer |

20ft*1 |

20ft*1 |

40ft*1 |

40ft*1 |

| With dryer |

40ft*1+20ft*1 |

40ft*2+20ft*1 |

40ft*2+20ft*1 |

40ft*3 |

| Remarks: 1. The Capacity calculated base on 30-packed egg tray(size 300x300mm, weight 70g~75g). 2. Workshop size is for reference only and could be adjusted according to actual size of client’s plant. |

Payment and delivery

| Trade terms |

FOB Qingdao or EXW Factory |

| Delivery time |

About 25 working days after receiving the deposit. |

| Payment term |

BY T/T 30%DEPOSIT+70%BALANCE. |

| Time of payment |

When the deposit is paid, the machine will begin to be produced. And the balance should be paid by the consignee (the buyer) before the delivery. |

| Warranty time |

Two years after the Egg tray machine received. |

| TERMS OF DELIVERY |

FOB Qingdao Port, China |

| Package |

In container |

| Certification |

CE |

Some world famous brands of the fittings:

1. the cylinder’s brand—FESTO

2. the electromagnetic valve’s brand—SHAKO

3. the pneumatic ball valve’s brand—SUPU

4. all the pump and motor are using famous brand of China.

5. the electric appliance’s brand—CHINT

6. the computer controller(PLC)--DELTA

7. the burner-- BALTUR/RIELLO

FAQ :

Our productionline has Fully Automatic and Semi Automatic two types , both have computer control system .

1. What is Semi Automatic type ?

If only order The 1st and 2nd compulsory parts , that's Semi Automatic because you'll have to do the work of drying up egg tray manually;

2. What is Fully Automat type ?

Meaning: the production line includes the Drying system and the whole procedure can be done Automatically .

Of course, the price and the required work space would have big difference from the semi-automatic type.

3. Quality

--- Our machines use UK Technics and part of the components are Germany-made (ex: Ball valve) .

-- Our machine is made by Tooling NOT by Welding , insuring a minimum of 10 years’ lifespan .

-- The Egg tray moulds material is Aluminium which can keep the fixed shape much better than that made of rubber material.

--- 99.9% of Success rate: Even if there is a failed egg tray , just throw it back to Pulping area and it can be re-used avoiding waste ;

--- Our machine has been sold to worldwide for over 10 years with continued re-order by some customers with their business grow .

Our machine can provide customer 2 years warranty, which no other factory can supply.

Welcome to contact us.

Machines on our factory

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!